Welding might seem like a basic process, but in our industry, it's an art form. Are you aware of how crucial precision welding is for achieving the ultra-high vacuum environments we provide? From semiconductor chambers to rocket engine components, the quality of our welds is paramount.

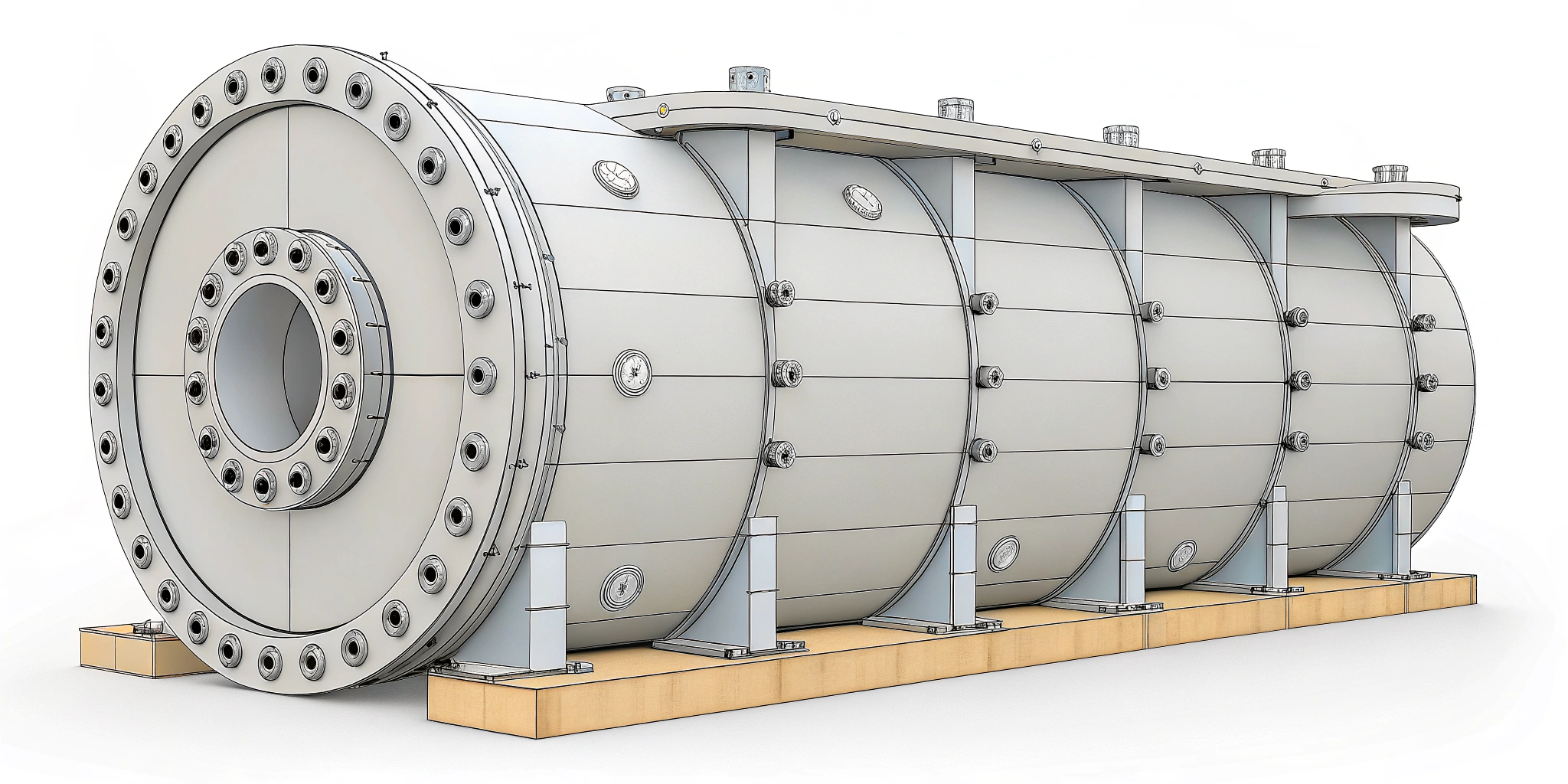

We specialize in creating custom-welded components that meet the most demanding specifications. I'll show you how we achieve airtight seals and structural integrity in our vacuum chambers and other products.

Let's explore the specific welding techniques we use and why they are essential for maintaining the integrity of our vacuum chambers and critical components.

Why is Precision Welding So Critical for Vacuum Applications?

Do you understand why ordinary welding just won't cut it for our vacuum chambers and scientific instruments? It's all about achieving and maintaining that perfect vacuum.

In vacuum technology, even the tiniest leak can compromise performance. Our precision welding ensures the airtight seals necessary for semiconductor manufacturing, scientific research, and aerospace applications 1. We guarantee the integrity of your vacuum environment.

Dive Deeper:

For vacuum applications, precision welding is not just a matter of joining materials; it's about creating a barrier against the intrusion of even the smallest particles or gases. In semiconductor manufacturing, where ultra-clean environments are essential, any leak can lead to contamination and defects in microchips. In scientific research, especially in fields like particle physics and materials science, a stable vacuum is necessary for accurate experiments and reliable data. In aerospace, where components must withstand extreme conditions, robust and leak-free welds are critical for safety and performance. By focusing on precision and airtightness, we ensure our vacuum chambers and components meet the stringent demands of these industries, enabling our clients to achieve their goals without compromise. Our welding processes are specifically tailored to minimize outgassing and prevent any form of leakage, guaranteeing the integrity of the vacuum environment.

Which Welding Techniques Do We Use to Guarantee Airtight Seals?

Are you curious about the specific welding methods we employ? It’s a combination of art and science, tailored to each project.

We primarily use Gas Tungsten Arc Welding (GTAW/TIG) and electron beam welding (EBW) 2. GTAW offers precise control for intricate geometries, while EBW is ideal for deep, narrow welds with minimal distortion. For commercial rocket engine welding, we also employ advanced processes under vacuum.

Dive Deeper:

Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is a highly versatile technique that allows our skilled welders to achieve precise control over the welding process. This is particularly important when working with complex geometries and sensitive materials commonly found in vacuum chambers. GTAW provides clean, high-quality welds with minimal spatter, reducing the risk of contamination and the need for extensive post-weld cleaning. Electron beam welding (EBW) is a more specialized technique that uses a focused beam of electrons to create deep, narrow welds with minimal heat-affected zones. This is ideal for joining thick sections of material or for applications where distortion must be kept to an absolute minimum, such as in the fabrication of large scientific devices. We have invested heavily in advanced EBW equipment to ensure that we can meet the most demanding requirements of our clients.

What Materials Do We Specialize In Welding for Vacuum Applications?

Do you know what kinds of materials we work with? It's more than just stainless steel – we handle a range of specialized alloys.

We specialize in welding stainless steel (304, 316L), aluminum alloys, titanium, and other specialized alloys commonly used in vacuum chambers and scientific instruments 3. Our expertise ensures optimal weld properties for each material.

Dive Deeper:

Our expertise in welding various materials for vacuum applications is a cornerstone of our ability to provide customized solutions. Stainless steel, particularly 304 and 316L, is a workhorse material for vacuum chambers due to its excellent corrosion resistance, low outgassing properties, and good weldability. Aluminum alloys are often chosen for their lightweight and high strength-to-weight ratio, making them ideal for aerospace and other applications where weight is a concern. Titanium offers exceptional strength and corrosion resistance, particularly in harsh environments, but it requires specialized welding techniques to prevent contamination. We also work with other specialized alloys, such as Inconel and molybdenum, to meet the unique requirements of our clients. By understanding the specific properties of each material and tailoring our welding processes accordingly, we can ensure that our welded components perform reliably in even the most demanding vacuum environments.

How Do We Ensure the Quality and Integrity of Our Welds?

What steps do we take to guarantee that our welds are not just good, but exceptional? Quality is non-negotiable for us.

We employ rigorous quality control procedures, including visual inspections, non-destructive testing (NDT) like X-ray and ultrasonic testing, and helium leak testing 4. Our welders are highly skilled and certified to meet industry standards.

Dive Deeper:

Ensuring the quality and integrity of our welds is a multi-faceted process that begins with careful material selection and preparation and continues through every stage of the welding process. Our welders are highly skilled and certified to meet or exceed industry standards, with ongoing training to keep them up-to-date on the latest techniques and best practices. Visual inspections are performed at each stage to identify any surface defects or irregularities. Non-destructive testing (NDT) methods, such as X-ray and ultrasonic testing, are used to detect internal flaws that may not be visible to the naked eye. Helium leak testing is the final step in the quality control process, where we use highly sensitive equipment to detect even the smallest leaks, ensuring that our vacuum chambers and components meet the most stringent airtightness requirements. Our commitment to quality is unwavering, and we continuously invest in new technologies and processes to further enhance the reliability of our welded products.

What Sets Our Welding Capabilities Apart in the Vacuum Technology Industry?

What makes our welding services stand out from the competition? It's our experience, equipment, and commitment to excellence.

Our combination of specialized equipment, experienced welders, and stringent quality control sets us apart 5. We understand the unique demands of vacuum technology and deliver solutions that exceed expectations. We understand vacuum applications and can deliver leak rates to 10^-11 or even 10^-12.

Dive Deeper:

What truly sets our welding capabilities apart in the vacuum technology industry is our deep understanding of the unique challenges and requirements of this field. We don't just weld components; we engineer solutions that are specifically designed to perform flawlessly in demanding vacuum environments. Our team of experienced welders has a proven track record of success in welding a wide range of materials and geometries, and they are constantly pushing the boundaries of what is possible. Our state-of-the-art equipment includes advanced GTAW and EBW systems, as well as specialized tools for material preparation, welding parameter control, and post-weld processing. Our stringent quality control procedures ensure that every weld meets our exacting standards, providing our clients with the confidence they need to succeed in their respective fields. We are committed to continuous improvement and innovation, always seeking new ways to enhance our welding capabilities and provide our clients with the best possible solutions.

Our precision welding capabilities are a cornerstone of our business, ensuring the highest quality vacuum chambers, scientific instruments, and rocket components. With skilled welders, advanced equipment, and rigorous quality control, we deliver airtight solutions for demanding applications.