When manufacturing vacuum chambers for semiconductor and panel display industries, selecting the right materials and finishes isn't just important—it's essential for success. At Laiku, we've learned through years of experience that these decisions directly impact performance, reliability, and longevity.

The ideal vacuum chamber material depends on your specific application requirements. Stainless steel offers excellent thermal stability and cleanliness, aluminum provides lighter weight with good machinability.

Our team at Laiku has developed deep expertise in vacuum chamber fabrication through years of hands-on experience. We've worked through countless design challenges and material selection issues, which has given us practical insight into what works and what doesn't in real-world applications.

Vacuum Chamber Materials

Choosing materials for your vacuum chamber project requires careful consideration of both performance characteristics and manufacturability. Our engineers always look at the complete picture when advising clients.

Stainless steel is widely used for vacuum chambers because of its excellent strength, thermal stability and minimal outgassing. Aluminum offers lighter weight and easier machining but presents different welding challenges.

At Laiku, we can recommend the right material for your application. Our manufacturing facilities are equipped with specialized tools and expertise to address the unique challenges posed by each material.

Stainless steel vacuum chambers remain the industry standard for many applications. The 304 grade is particularly popular for its combination of properties. We've refined our welding and finishing processes specifically for stainless steel to ensure consistent vacuum integrity.

Aluminum chambers offer significant weight advantages and excellent machinability. Rather than welding multiple pieces together, we can often machine entire chambers from solid aluminum billets, substantially reducing potential leak points. This approach has helped many of our customers achieve better vacuum performance.

Vacuum Chamber Finishes

The surface finish of your vacuum chamber dramatically affects its performance. Different applications require different finishing approaches, and we offer several options to meet specific needs.

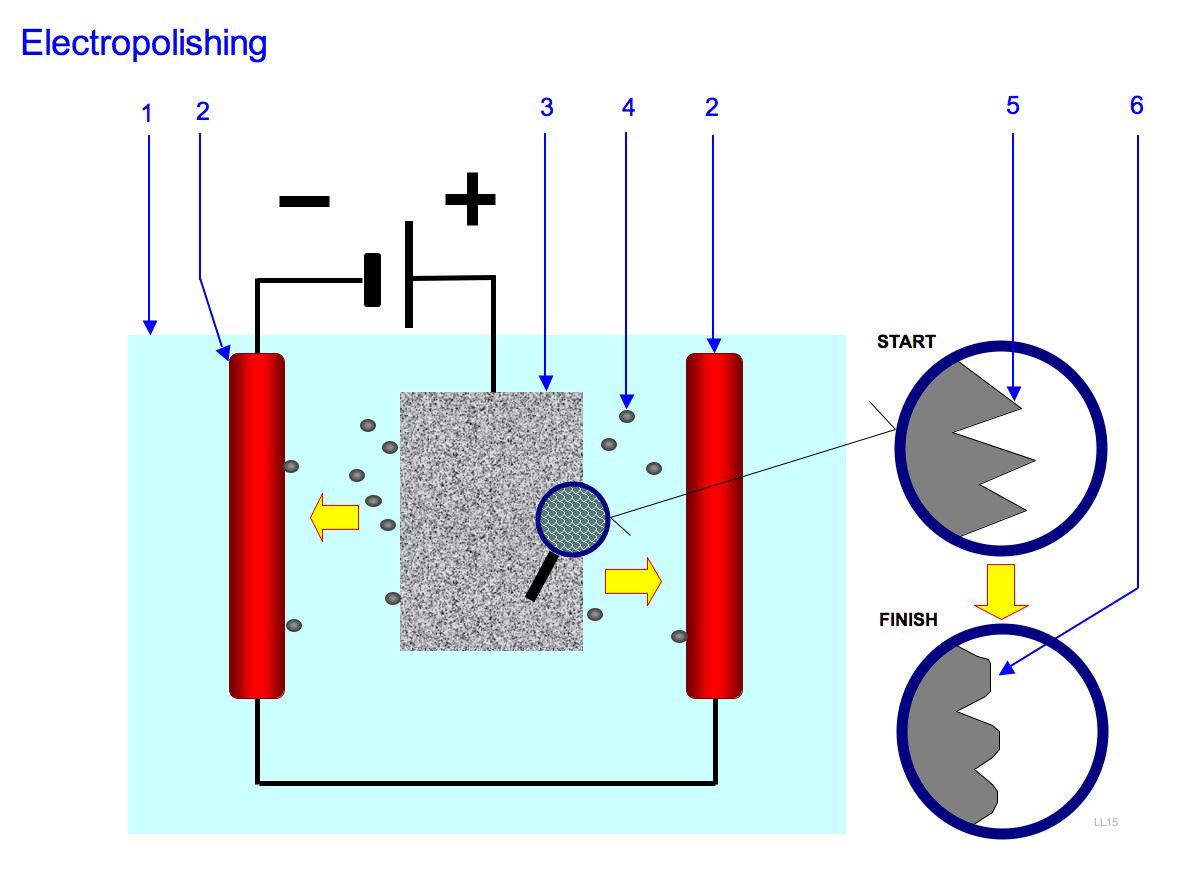

The right surface finish reduces outgassing rates and improves overall vacuum performance. Options include electropolishing for superior surface smoothness, bead blasting for uniform preparation, hand polishing for critical areas, and specialized plating for enhanced conductivity or reduced gas release.

Each finishing method serves a specific purpose in vacuum chamber manufacturing:

Bead blasting provides a uniform surface preparation that seals and levels the surface. We often use this technique to prepare surfaces for subsequent plating or as a standalone finish for less demanding applications.

Hand polishing is particularly valuable for critical sealing surfaces or areas where tooling marks must be completely removed. Our skilled technicians apply years of experience to achieve the exact surface characteristics needed.

Electropolishing creates an exceptionally smooth surface that significantly reduces outgassing—a critical factor for ultra-high vacuum applications. This electrochemical process removes microscopic peaks from the surface, decreasing the effective surface area that can trap gases.

With 25 years of experience in the machining industry, our team can help optimize your machining solutions, effectively saving on material and time costs while ensuring all performance requirements are met. We work closely with our clients to find the most cost-effective solutions.

Contact us to discuss your vacuum chamber needs and discover how Laiku's experience can help ensure the success of your project.