Many of our customers ask this fundamental question when beginning vacuum chamber projects. The short answer is no, but understanding why reveals fascinating physics and practical engineering considerations that impact your real-world applications.

A perfect (100%) vacuum—completely empty space with absolutely no particles—is theoretically impossible to achieve. Even in deep space, there are a few atoms per cubic meter. In practical applications, we work with "high" or "ultra-high" vacuum levels that sufficiently meet technical requirements while acknowledging that some particles always remain.

As vacuum technology specialists at Laiku, we've spent years pushing the boundaries of what's possible in vacuum creation. Let me explain the fascinating physics behind this question and how it impacts your projects.

Why Is a Perfect Vacuum Impossible?

The challenge of creating a perfect vacuum goes beyond just our current technological capabilities—it involves fundamental physical limitations that affect every vacuum system design.

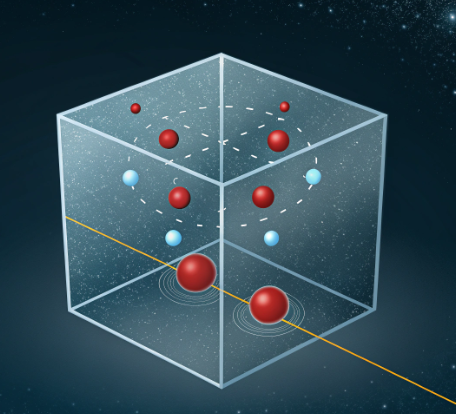

A perfect vacuum is impossible because of quantum physics principles, outgassing from chamber materials, and the omnipresent virtual particles that continuously appear and disappear in space. Even the most advanced vacuum systems can only approach, but never reach, absolute emptiness.

When we discuss vacuum quality at Laiku, we're talking about degrees of vacuum rather than absolute emptiness. The quantum world presents fascinating obstacles to creating perfect vacuums. According to quantum field theory, even in completely empty space, virtual particles continuously pop in and out of existence. These quantum fluctuations mean that no space can ever be truly empty.

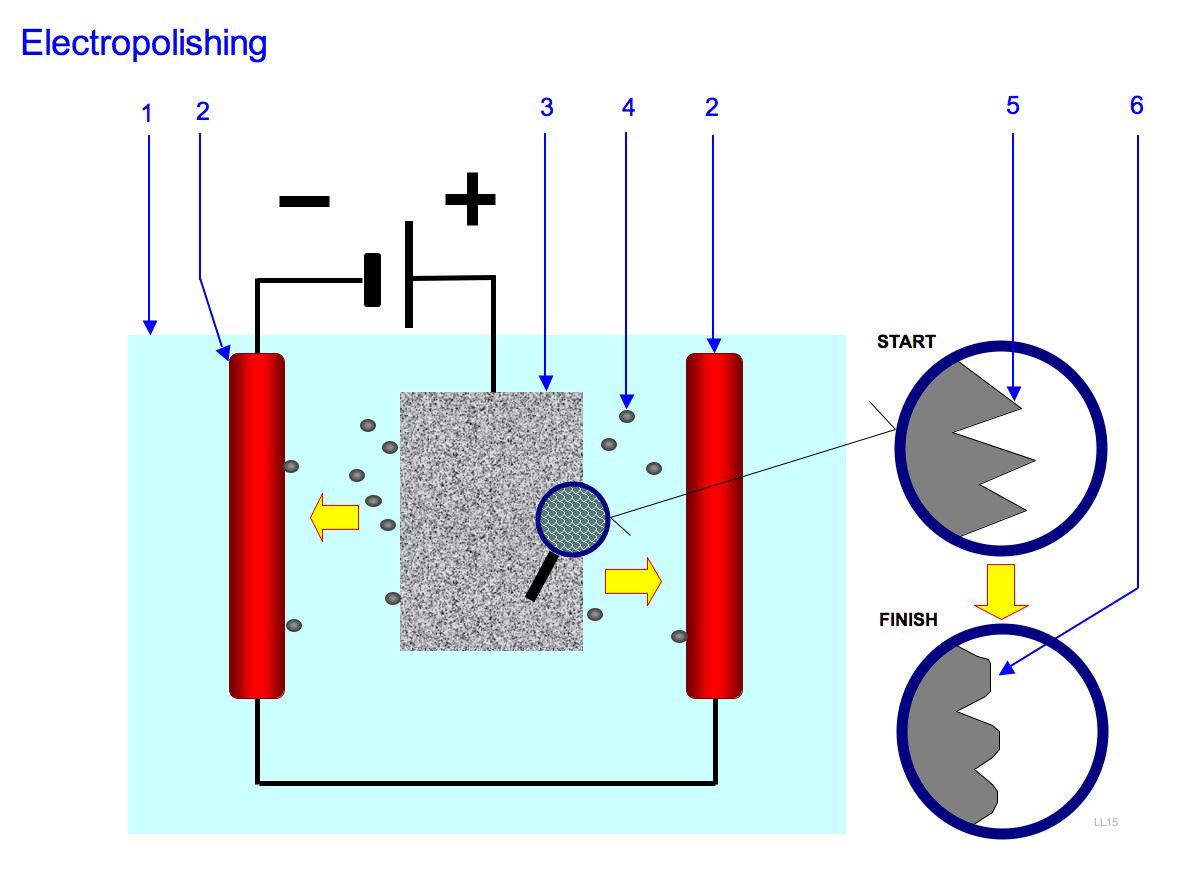

From a practical engineering perspective, several other factors prevent perfect vacuums. Chamber materials constantly release trapped gases through a process called outgassing. This happens regardless of material purity, though some materials outgas less than others. At Laiku, we carefully select materials with minimal outgassing properties and apply specialized treatments to reduce this effect.

Even the most advanced pumping technologies cannot remove all particles. As vacuum levels increase, removing the remaining particles becomes exponentially more difficult. This is why there's a practical limit to the vacuum levels achievable even with state-of-the-art equipment.

Temperature also plays a crucial role—higher temperatures increase molecular movement and outgassing rates. This is why some ultra-high vacuum applications require cooling systems to achieve their target vacuum levels.

What Vacuum Levels Are Actually Achievable?

Understanding the practical vacuum levels that can be achieved helps set realistic expectations for your applications and guides proper equipment selection.

Modern vacuum technology can achieve ultra-high vacuum levels of 10^-12 Torr (approximately 10^-10 Pascal) in carefully designed systems. These extreme vacuums require specialized materials, baking procedures to remove water vapor, and multiple pumping technologies working together.

凭借我们25年的机械加工行业丰富经验,莱库团队可以帮助优化您的加工方案,有效节省材料成本和时间成本,同时确保满足所有性能要求。我们与客户紧密合作,找到最具成本效益的解决方案。

At Laiku, we classify vacuum levels into several categories based on pressure ranges:

| Vacuum Type | Pressure Range (Torr) | Typical Applications |

|---|---|---|

| Rough Vacuum | 760 to 1 | Basic material handling, vacuum packaging |

| Medium Vacuum | 1 to 10^-3 | Thermal insulation, some coating processes |

| High Vacuum | 10^-3 to 10^-8 | Electron microscopy, thin film deposition |

| Ultra-High Vacuum | 10^-8 to 10^-12 | Semiconductor processing, surface physics research |

| Extreme Ultra-High Vacuum | Below 10^-12 | Specialized physics experiments |

Different applications require different vacuum levels. For instance, semiconductor manufacturing might require high or ultra-high vacuum levels, while food packaging only needs rough vacuum. Understanding your specific requirements helps determine the appropriate technology and investment needed.

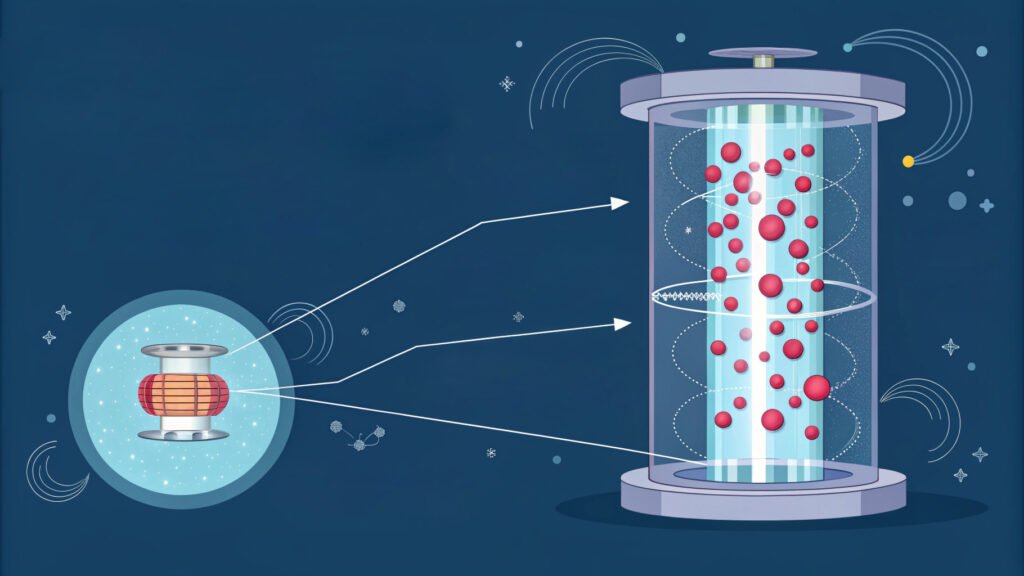

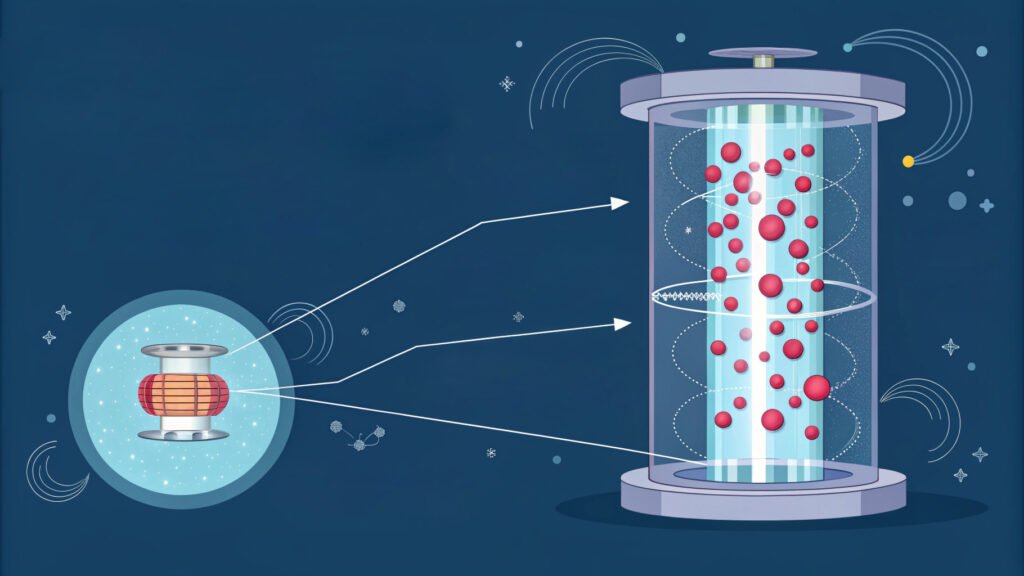

Achieving ultra-high vacuum levels requires sophisticated pumping systems typically combining multiple technologies. We often use a combination of mechanical pumps for initial evacuation, turbomolecular pumps for the middle range, and ion pumps for achieving and maintaining the highest vacuum levels.

How Do We Measure Vacuum Quality?

Measuring a vacuum accurately is just as important as creating it. The methods and instruments we use depend on the vacuum range and application requirements.

Vacuum quality is measured with specialized gauges appropriate for different pressure ranges. Mechanical gauges work for rough vacuum, while ionization gauges measure high and ultra-high vacuum levels. Modern vacuum systems typically employ multiple gauge types to provide accurate readings across the entire pressure range.

Vacuum measurement is a specialized field requiring appropriate instrumentation for each pressure range. At Laiku, we use a variety of gauges depending on the application:

-

Mechanical gauges like diaphragm and capsule gauges work well for rough vacuum levels but lose accuracy at higher vacuums.

-

Thermal conductivity gauges such as Pirani gauges measure medium vacuum levels by detecting changes in heat transfer between molecules.

-

Ionization gauges become essential for high and ultra-high vacuum measurements. These gauges ionize the remaining gas molecules and measure the resulting current to determine pressure.

-

Mass spectrometers not only measure vacuum levels but also analyze the composition of residual gases, providing valuable information about potential contamination sources.

For critical applications, we often install multiple gauge types to ensure accurate readings across the entire evacuation process. This comprehensive approach helps validate system performance and troubleshoot potential issues.

Conclusion

While a 100% perfect vacuum remains physically impossible, the advanced vacuum levels we can achieve today are more than sufficient for even the most demanding industrial and scientific applications. Understanding these principles helps set realistic expectations and guides proper equipment selection.