Ultra-high vacuum environments create significant challenges for welding and connections. Leaks, contamination, and material failures can compromise system performance and lead to costly production delays in semiconductor manufacturing.

Successfully addressing ultra-high vacuum welding challenges requires specialized techniques like friction stir welding and electron beam welding, combined with proper material selection, clean room processing, and comprehensive testing to maintain vacuum integrity below 10^-12 Pa·m³/s.

At Laiku, I've seen how these specialized approaches transform challenging connections into reliable vacuum systems. Let me share what truly makes the difference.

What Materials Best Suit Ultra-High Vacuum Applications?

Poor material choices lead to outgassing issues that compromise vacuum integrity. Many manufacturers overlook crucial material characteristics that affect long-term performance.

The best materials for ultra-high vacuum applications include 304L/316L stainless steel, titanium, and specialized aluminum alloys with minimal outgassing properties. These materials maintain excellent weldability while providing the dimensional stability required for precision equipment.

Beyond just selecting the right grade, we control material chemistry strictly. For example, we maintain sulfur levels in stainless steel below 0.005% for critical components, as this significantly impacts weld quality and vacuum performance.

Which Welding Techniques Ensure Ultra-High Vacuum Integrity?

Traditional welding approaches often create microscopic pathways for leakage. Many manufacturers struggle with consistency, especially on large chambers.

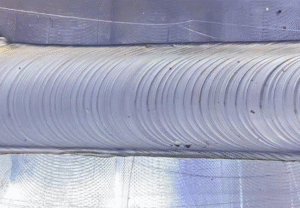

Superior vacuum welding techniques include friction stir welding for aluminum and electron beam welding for precision joints. These approaches minimize heat-affected zones, eliminate porosity, and maintain critical dimensional tolerances of ±0.05mm per meter.

Our friction stir welding expertise comes from specialists with 27 years of experience serving Applied Materials. This solid-state joining process maintains material properties while dramatically reducing distortion. For stainless steel, our electron beam welding system operates in a vacuum environment, producing incredibly clean welds with minimal heat effects.

How Important is Clean Processing for Vacuum Components?

Contamination during manufacturing creates persistent vacuum issues that compromise performance. Even microscopic particles can affect vacuum integrity.

Clean room processing is essential, requiring controlled environments from Class 10,000 down to Class 100 for final assembly. This prevents contamination and ensures components meet the stringent requirements of advanced semiconductor processes.

In our facilities, components move through progressively cleaner environments as they advance through production. Final assembly occurs in Class 100 areas with continuous particle monitoring. Our strict material segregation protocols prevent cross-contamination between standard and ultra-high vacuum components.

Conclusion

Addressing ultra-high vacuum welding challenges requires specialized materials, advanced techniques, and meticulous processing. By implementing these approaches, manufacturers can create vacuum systems that meet the demanding requirements of today's semiconductor industry while maintaining crucial vacuum integrity.