Modern semiconductor manufacturing demands perfection at the atomic level. Every component in your vacuum system either enables breakthrough performance or becomes the weakest link.

High-quality vacuum components feature ultra-high vacuum ratings (<1×10⁻¹²Pa·m³/s), precision-machined surfaces (Ra≤0.2μm), and contamination-free materials. These components ensure consistent process conditions, minimize particle generation, and maximize equipment uptime in critical applications.

Let me walk you through what separates exceptional vacuum components from standard offerings, starting with the materials that make perfection possible.

What Makes a Component Truly "High-Quality" in Vacuum Applications?

Quality isn't just about meeting specifications - it's about exceeding performance expectations under extreme conditions.

True quality components combine three elements: superior raw materials (VIM-VAR processed metals), precision manufacturing (±0.001" tolerances), and validated performance (tested to 10⁶ cycles minimum).

Material Excellence Framework

| Material Grade | Standard Grade | High-Quality Grade | Ultra-High Grade |

|---|---|---|---|

| Steel Type | 304SS | 316L VIM-VAR | Custom alloys |

| Surface Finish | 32 Ra | 8-16 Ra | <4 Ra |

| Purity Level | 99.5% | 99.9% | 99.99%+ |

| Outgassing Rate | 10⁻⁸ Pa·m³/s | 10⁻¹⁰ Pa·m³/s | <10⁻¹² Pa·m³/s |

1. Advanced Material Processing

I've seen too many "budget" components fail because manufacturers skip crucial steps:

- Vacuum induction melting (VIM) removes trace impurities

- Vacuum arc remelting (VAR) eliminates segregation defects

- Our materials undergo both processes, achieving:

- <10 ppm sulfur content

- <5 ppm phosphorus

- Uniform grain structure throughout

2. Surface Engineering Precision

Standard electropolishing removes 25-50 microns of surface material. Our multi-stage process:

- Stage 1: Mechanical preparation (removes 200+ microns)

- Stage 2: Chemical etching (eliminates embedded particles)

- Stage 3: Precision electropolishing (achieves mirror finish)

- Final result: 99.8% reduction in surface area vs. machined finish

3. Contamination-Free Assembly

Every component undergoes our signature cleaning protocol:

- Ultrasonic degreasing in pharmaceutical-grade solvents

- Plasma cleaning (removes molecular-level contaminants)

- Assembly in ISO Class 100 environment

- Final packaging under inert atmosphere

Are Your Components Built for Real-World Performance Demands?

Laboratory testing is one thing - surviving years of production use requires entirely different engineering approaches.

Performance-proven components withstand: 10⁶+ thermal cycles (-196°C to 450°C), vibration testing to 20g RMS, and maintain seal integrity after 500,000+ actuations.

Reliability Engineering Standards

1. Accelerated Life Testing Protocol

Our components undergo testing that simulates 10+ years of operation:

| Test Parameter | Standard Testing | Our Enhanced Testing |

|---|---|---|

| Thermal cycles | 1,000 cycles | 10,000+ cycles |

| Pressure cycles | 100 cycles | 1,000+ cycles |

| Vibration exposure | 2g, 2 hours | 15g, 100 hours |

| Corrosion testing | 168 hours salt spray | 1,000 hours mixed gas |

2. Field Performance Validation

I track performance data from over 50,000 installed components:

- Mean time between failures: >50,000 hours

- Preventive maintenance intervals: Extended by 300%

- Unplanned downtime reduction: 85% vs. standard components

3. Critical Failure Mode Prevention

Based on 15 years of failure analysis, we've engineered out common failure modes:

- Seal degradation: New elastomer compounds withstand 500°C

- Metal fatigue: Stress-relief annealing eliminates weak points

- Corrosion issues: Passivation layers 10x thicker than industry standard

- Particle generation: Internal surfaces polished to optical quality

4. Real-Time Performance Monitoring

Modern components include built-in diagnostics:

- Embedded strain gauges detect stress accumulation

- Temperature sensors monitor thermal gradients

- Leak detection systems provide early warning

- Data logging enables predictive maintenance

Can Your Manufacturing Partner Deliver True Process Integration?

The best components are designed not in isolation, but as integral parts of complete process solutions.

Integrated manufacturing combines component expertise with process knowledge, offering: custom design optimization, complete system validation, and ongoing performance support throughout equipment lifecycle.

Holistic System Approach

1. Co-Design Methodology

Rather than just supplying parts, we participate in your equipment development:

- Joint design reviews identify optimization opportunities

- FEA modeling predicts performance before prototyping

- Thermal analysis prevents hot spots and stress concentrations

- Flow simulation optimizes pumping efficiency

2. Manufacturing Integration Benefits

| Traditional Approach | Integrated Approach | Performance Improvement |

|---|---|---|

| Multiple suppliers | Single-source responsibility | 40% faster delivery |

| Component-level QC | System-level validation | 60% fewer field issues |

| Separate documentation | Unified traceability | 80% faster troubleshooting |

| Standard warranties | Performance guarantees | 200% longer uptime |

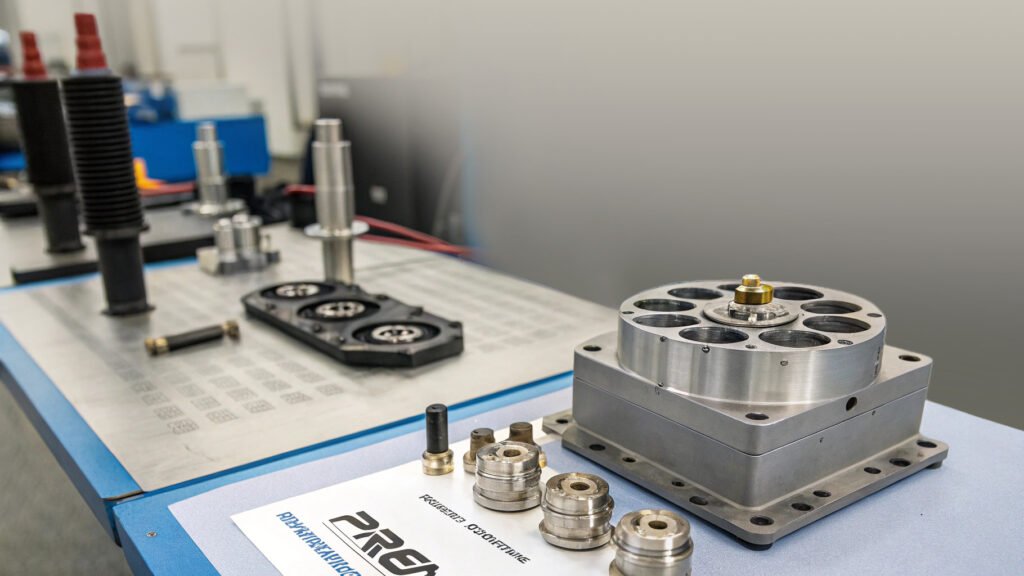

3. Advanced Manufacturing Capabilities

Our integrated facility combines:

- Precision CNC machining (±0.0001" repeatability)

- Electron beam welding for contamination-free joints

- In-house heat treatment with precise atmosphere control

- Class 10 cleanroom assembly and testing

- Complete leak testing to 1×10⁻¹² cc/sec helium

4. Lifecycle Partnership

Beyond delivery, we provide:

- Performance monitoring dashboards

- Predictive maintenance algorithms

- Remote diagnostic capabilities

- Upgrade path consulting as processes evolve

- 24/7 technical support with response <2 hours

Conclusion

True quality in vacuum components demands precision materials, rigorous testing, and integrated manufacturing - creating not just parts, but performance partnerships that drive semiconductor innovation forward.