Panel display manufacturers need radical innovations to stay competitive in a rapidly evolving market. Off-the-shelf vacuum chambers often limit process capabilities and stifle innovation.

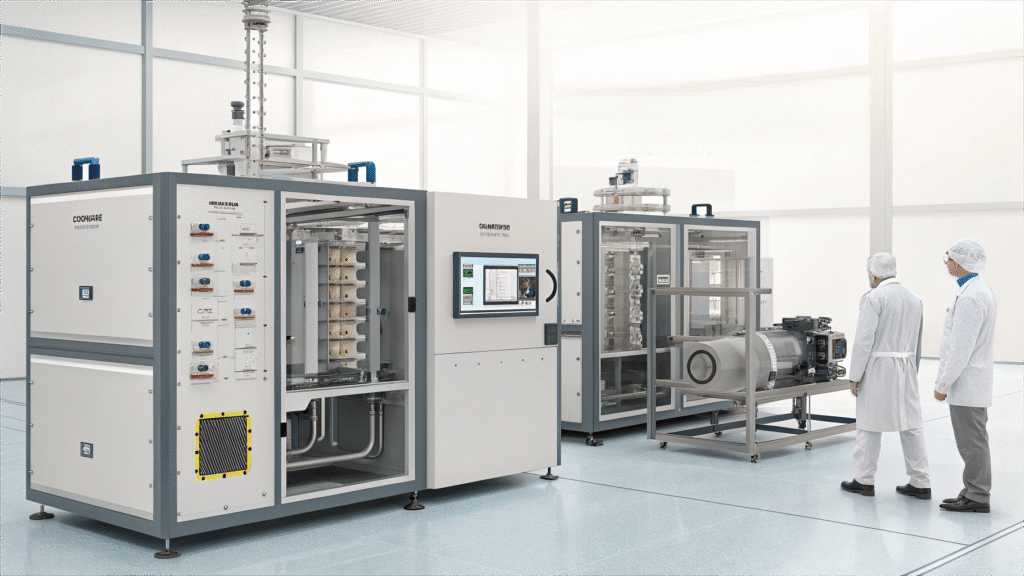

Customized vacuum chambers unlock new possibilities for panel display technology by enabling unique process configurations, optimized material deposition, and precise control over critical parameters. These tailored solutions facilitate breakthroughs in display resolution, energy efficiency, and manufacturing efficiency.

The panel display industry is driven by relentless innovation, with manufacturers constantly pushing the boundaries of resolution, color gamut, energy efficiency, and form factor. Customized vacuum chambers are not merely an option, but a necessity for companies seeking to lead in this competitive landscape. Let's explore how bespoke engineering of vacuum systems can catalyze breakthroughs in display technology.

What Unique Process Capabilities Can Customized Chambers Enable?

Panel display manufacturers are limited by the rigid configurations of standard vacuum chambers. Unique deposition techniques and novel material integrations often require chamber designs that don't exist off-the-shelf.

Customized vacuum chambers enable specialized process capabilities including angled deposition, dynamic substrate manipulation, and multi-source material integration. These unique configurations allow manufacturers to explore novel display architectures and achieve performance benchmarks impossible with standard equipment.

Customized vacuum chambers for panel display manufacturing enable a range of unique process capabilities that drive innovation beyond the limitations of standard equipment. These tailored solutions provide the flexibility to implement cutting-edge deposition techniques, integrate novel materials, and precisely control critical process parameters.

One significant advantage is the ability to implement non-standard deposition geometries. Traditional vacuum chambers typically provide deposition sources positioned perpendicular to the substrate surface, limiting the ability to create complex thin film structures with tailored optical or electrical properties. Customized chambers can incorporate angled deposition sources that allow for conformal coating of intricate features or the creation of graded index films with continuously varying refractive index. These capabilities are crucial for advanced display technologies like microLEDs and quantum dot displays.

Dynamic substrate manipulation represents another area where customized chambers offer significant advantages. Standard vacuum systems often rely on static substrate holders, limiting the ability to optimize film uniformity or address local variations in deposition rate. Customized chambers can incorporate sophisticated substrate rotation, tilt, and translation mechanisms that enable precise control over film thickness and composition across the entire substrate surface. These capabilities are essential for large-area deposition on flexible substrates.

Multi-source material integration presents another opportunity for customized vacuum chamber design. Standard systems typically accommodate a limited number of deposition sources, restricting the ability to create complex multilayer films or co-deposit multiple materials simultaneously. Customized chambers can incorporate a diverse array of deposition sources including thermal evaporators, sputtering sources, and atomic layer deposition modules, allowing for precise control over film stoichiometry and interface properties. This is particularly relevant for organic LED (OLED) displays where precise control of multiple organic layers is critical for achieving high efficiency and color purity.

Furthermore, customized vacuum chambers can integrate advanced process monitoring capabilities that provide real-time feedback on film properties during deposition. These systems can incorporate in-situ ellipsometry, quartz crystal microbalances, and optical emission spectroscopy to monitor film thickness, refractive index, and elemental composition. This real-time feedback allows for dynamic adjustment of process parameters to ensure optimal film quality and uniformity.