Choosing the right vacuum chamber isn't just about sealing. It's about precision, cleanliness, and advanced technology working together for flawless semiconductor production.

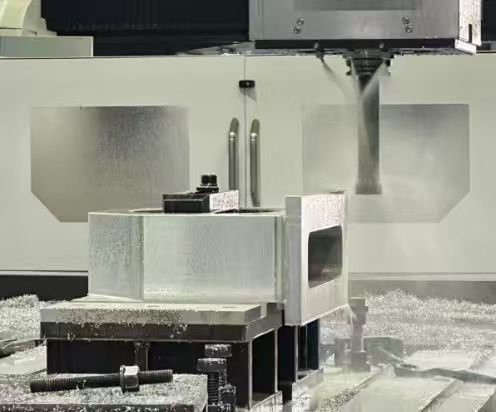

A top-tier vacuum chamber meets ultra-high vacuum standards (<1.0×10⁻¹²Pa·m³/s), controls contamination at ppt levels, and maintains dimensional stability (±0.05mm/m). Its manufacturing requires precision welding, surface treatments, and real-time process monitoring.

Let's break down the critical factors that separate exceptional vacuum chambers from average ones, starting with materials and surface treatments.

Does Your Checklist Cover These Critical Technical Specifications?

Many buyers focus only on basic vacuum levels, missing crucial parameters that determine real-world performance.

Beyond vacuum ratings, verify these specs: surface roughness (Ra≤0.4μm), outgassing rate (<10⁻¹⁰Pa·m³/s/m²), particulate counts (<5 particles/ft³ at 0.1μm), and leak rates (<1×10⁻¹²Pa·m³/s helium).

Material Selection Breakdown

| Material Type | Advantages | Limitations | Best Applications |

|---|---|---|---|

| 316L VIM-VAR Stainless | Lowest outgassing | Higher cost | EUV lithography |

| Aluminum alloys | Lightweight | Limited bakeout temp | Transport systems |

| Titanium alloys | Corrosion-resistant | Difficult machining | Harsh environments |

-

Surface Treatments Matter More Than You Think

- Electrochemical polishing reduces surface area by 80% vs mechanical polishing

- Our proprietary cleaning process achieves:

- <0.1 ng/cm² hydrocarbon residue

- <0.5 nm surface oxide layer

-

Welding Technology Differences

- Conventional TIG welding: 5-10 μm surface irregularities

- Our friction-stir welding: <1 μm uniformity

- All welds undergo:

- 100% helium leak testing

- X-ray inspection

- Residual gas analysis

Are You Overlooking These Manufacturing Process Controls?

Even perfect designs fail with substandard production controls - here's what truly separates manufacturers.

Elite vendors implement: Class 100 cleanrooms, humidity-controlled welding (40±5% RH), real-time SPC monitoring, and full digital traceability covering 200+ process parameters.

Critical Process Monitoring Points

1. Environmental Controls

- Temperature: 20±0.5°C

- Vibration: <5 μm/s (ISO 1940 balance grade)

- Airflow: Laminar flow at 0.45±0.05 m/s

2. Quality Assurance Layers

- Incoming material certification (traceable to NIST)

- In-process checks (hourly dimensional verification)

- Final validation testing:

- 48-hour bakeout at 250°C

- Residual gas analysis

- Particulate mapping

3. Digital Traceability System

| Data Type | Sampling Frequency | Storage Duration |

|---|---|---|

| Weld parameters | 100Hz | 10 years |

| Cleanroom conditions | Every minute | 5 years |

| QC measurements | Per unit | Lifetime |

Can Your Supplier Deliver True Collaborative Engineering?

Modern semiconductor processes demand co-development, not just procurement transactions.

Leading partners provide: early-stage DFM feedback, FEM simulation services (thermal/structural), and joint process development with shared testing data.

Stages of Effective Co-Development

-

Concept Phase

- Review 20+ design parameters with equipment OEMs

- Run preliminary thermal/stress simulations

- Identify material compatibility risks

-

Prototyping

- Build functional mockups in 30% less time than competitors

- Conduct accelerated life testing

- 1000 thermal cycles (-196°C to 350°C)

- Vibration testing to 15g RMS

-

Production Ramp-Up

- Implement statistical process control

- Establish failure mode databases

- Develop customized cleaning protocols

Our client engagements show this approach reduces:

- Development cycles by 40%

- Production costs by 18-25%

- Field failures by 90%

Conclusion

Exceptional vacuum chambers combine extreme precision materials, advanced manufacturing controls, and collaborative engineering - delivering not just components but process-enabling solutions.

2 Responses

Hi, I do think this is an excellent blog. I stumbledupon it 😉 I may revisit once again since i have saved as a favorite it. Money and freedom is the best way to change, may you be rich and continue to help others.

Thank you for your support and best wishes! We’re glad to know you enjoy our blog. Providing valuable information is our greatest motivation. Please feel free to visit again and share your thoughts and suggestions. May we all achieve success and freedom while helping others. Thank you again for your encouragement!