High-Precision Vacuum

Solutions for

Semiconductor

Manufacturing

Custom-engineered high-vacuum chambers and components that meet the most demanding semiconductor process requirements.

Addressing Critical Challenges in Semiconductor Manufacturing

The semiconductor industry is currently facing many problems that need to be solved

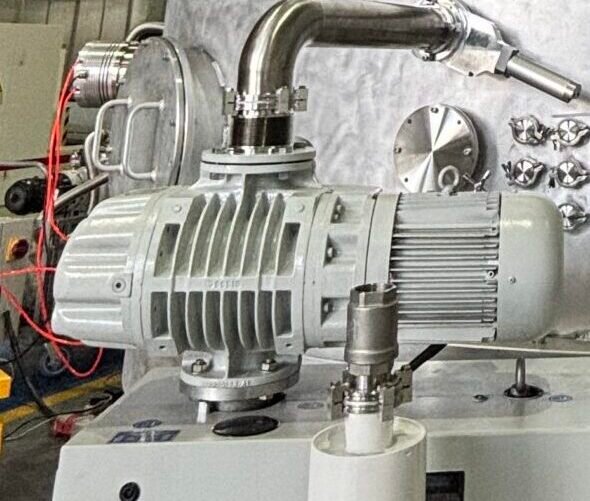

Modern semiconductor processes have increasingly higher requirements for chamber vacuum (<1×10^-7 Pa), and traditional manufacturing processes are difficult to meet the needs of advanced processes.

-

Laiku has achieved a breakthrough in ultra-high vacuum

(< 10^-7Pa ) technology, with a leakage rate (<1.0×10^-13 Pa·m³/s).

Precision control and deformation issues in large-size cavity processing. Poor deformation control will seriously affect the performance and yield of semiconductor equipment.

- Laiku has mastered high-precision deformation control technology, and the deformation tolerance is controlled within (±0.05mm/m).

Semiconductor processes have strict requirements on component cleanliness, and even a trace of contamination can lead to a decrease in chip yield

- Equipped with constant temperature and humidity welding rooms, Class 10,000, Class 1000 and Class 100 clean rooms, providing a full-process clean solution from processing to clean assembly.

The complex cavity structures in modern semiconductor devices require high-precision machining, especially for aluminum alloy parts that are difficult to weld.

- Provides a variety of advanced welding processes such as TIG welding and friction stir welding (FSW), especially suitable for complex geometries and high-quality joints in semiconductor device manufacturing.

The instability of the global supply chain has led to extended delivery times and unstable quality of core components of semiconductor equipment

- Providing complete supply chain services from raw materials, machining, welding to surface treatment and clean assembly can help you save time and improve efficiency

Semiconductor technology is rapidly iterating, and equipment manufacturers need partners who can quickly respond to customized needs

- Laiku focuses on providing customized solutions and has a team of high-end technical talents who can provide customers with customized services from chambers to complete systems.

Precision-Engineered Solutions for Semiconductor Equipment Manufacturers

The product series we provide are widely used in lithography, ion implantation, thin film deposition, dry etching and other links.

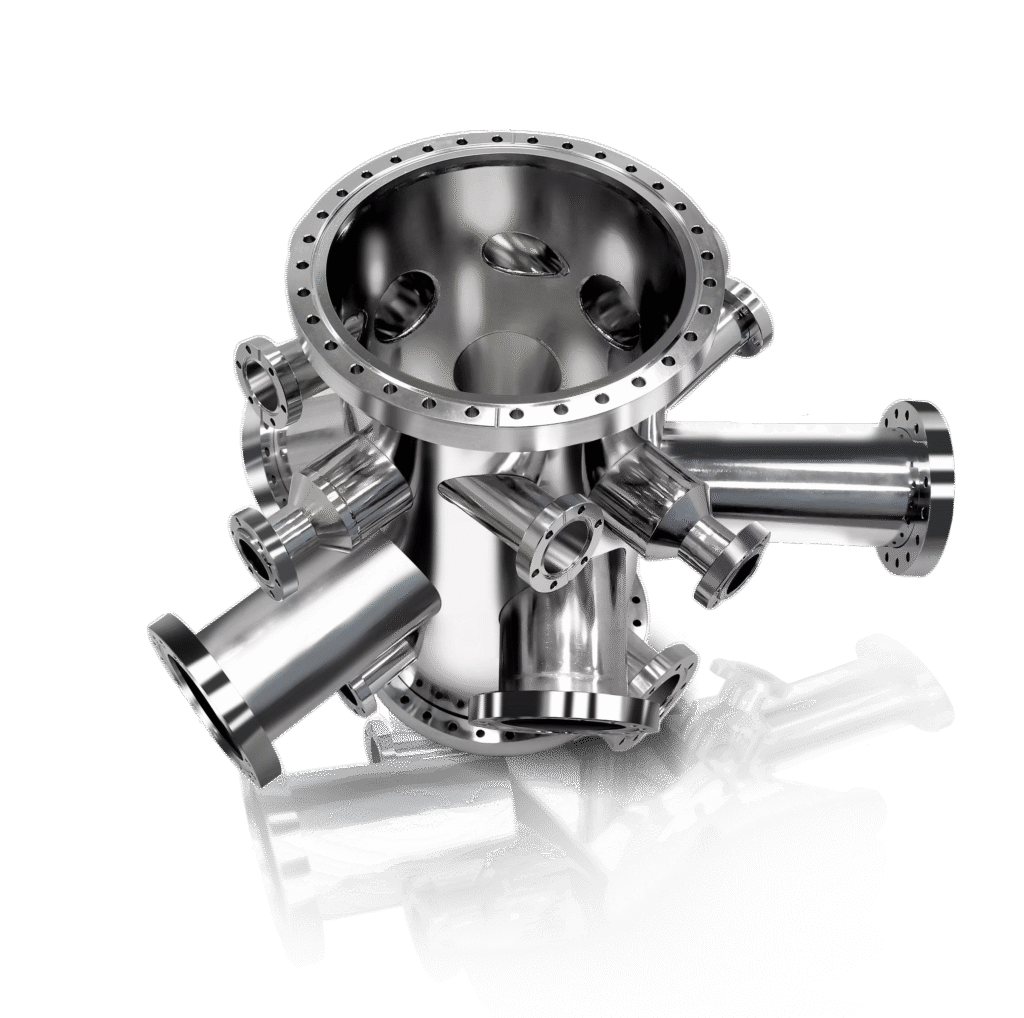

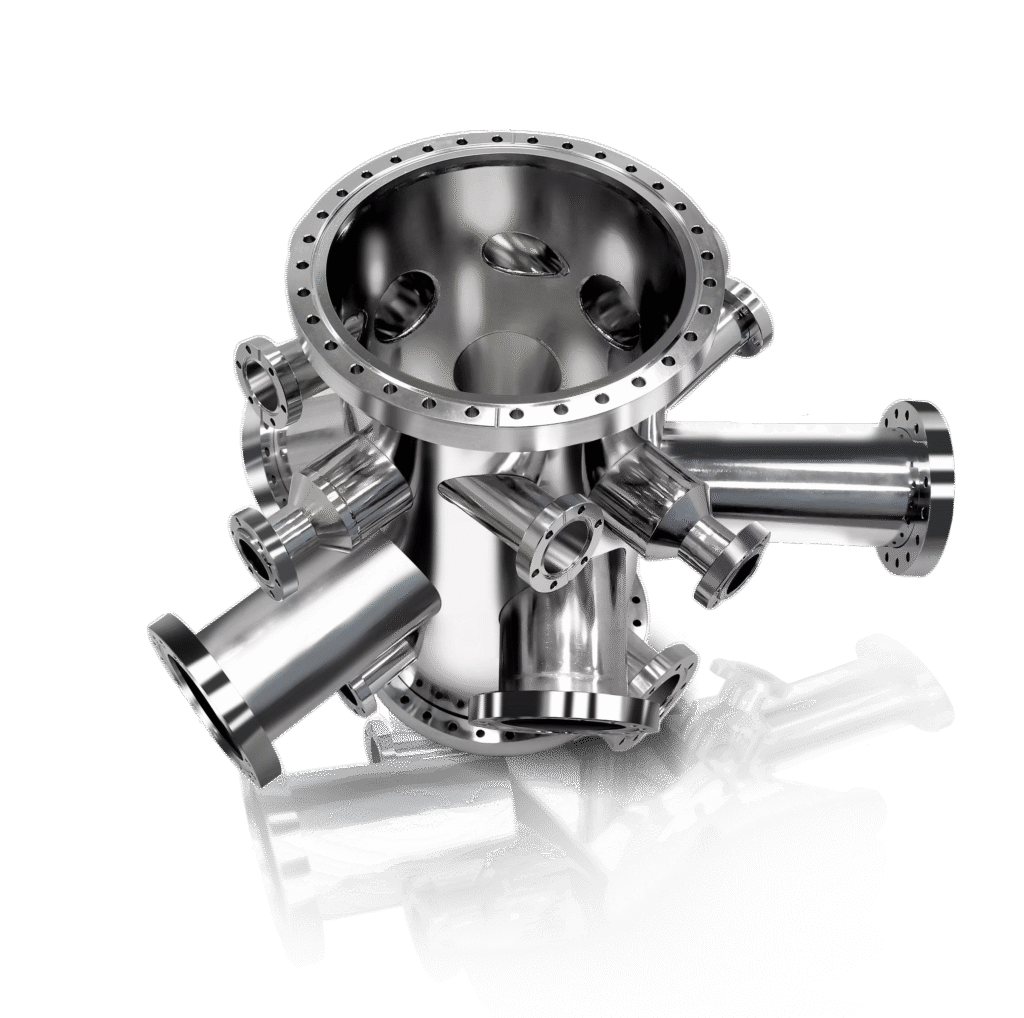

Spherical stainless steel vacuum chamber

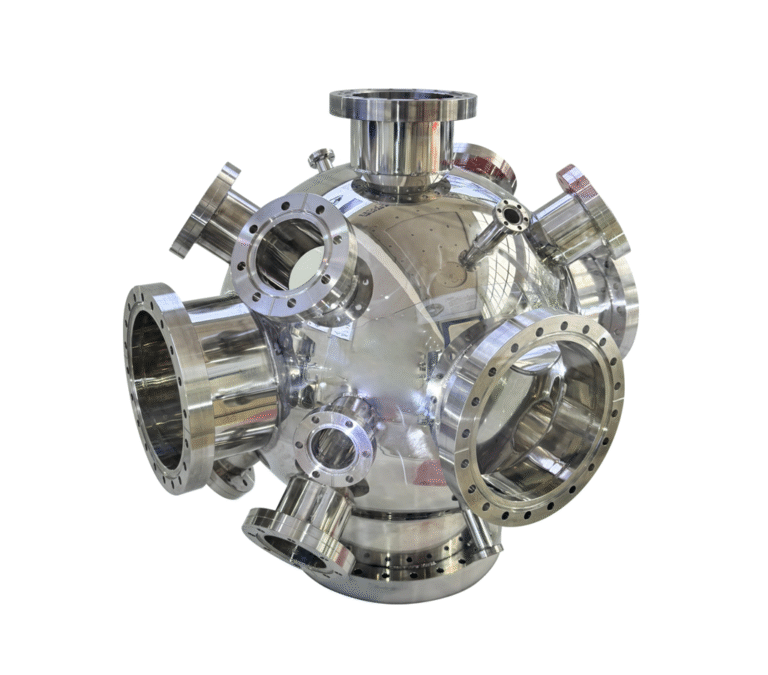

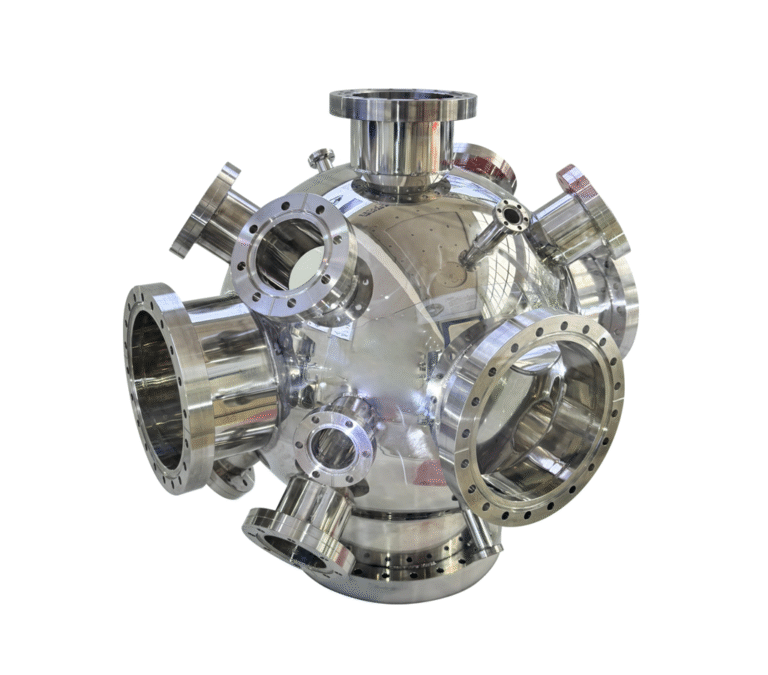

Cylindrical stainless steel vacuum chamber

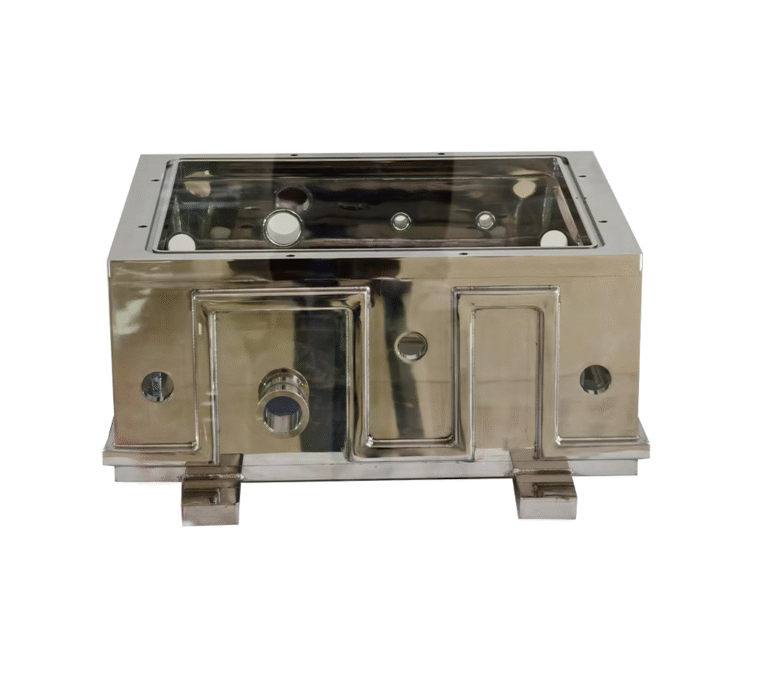

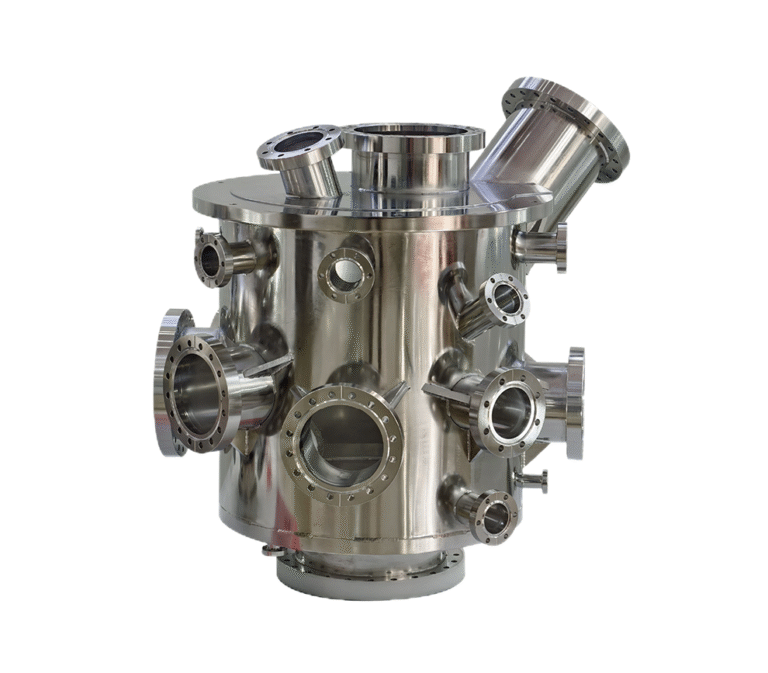

Square stainless steel vacuum chamber

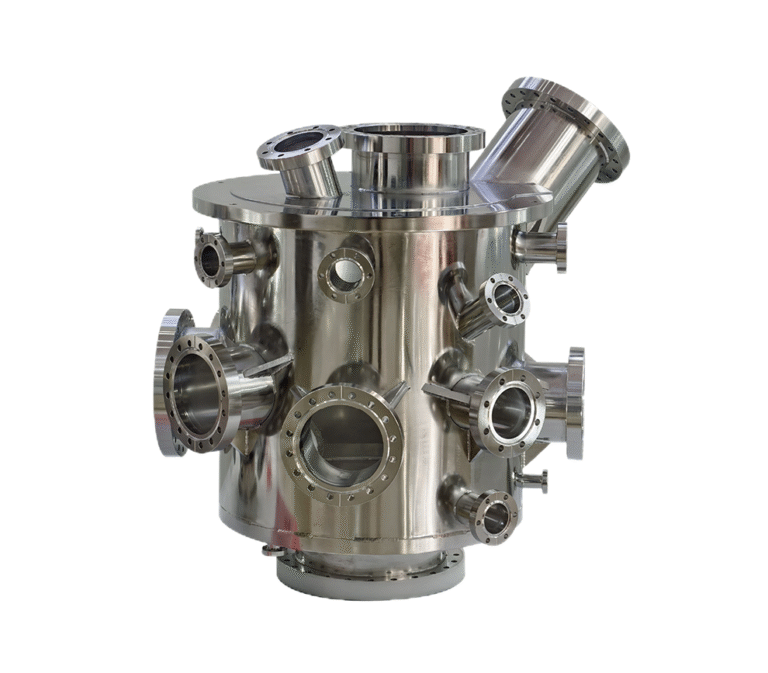

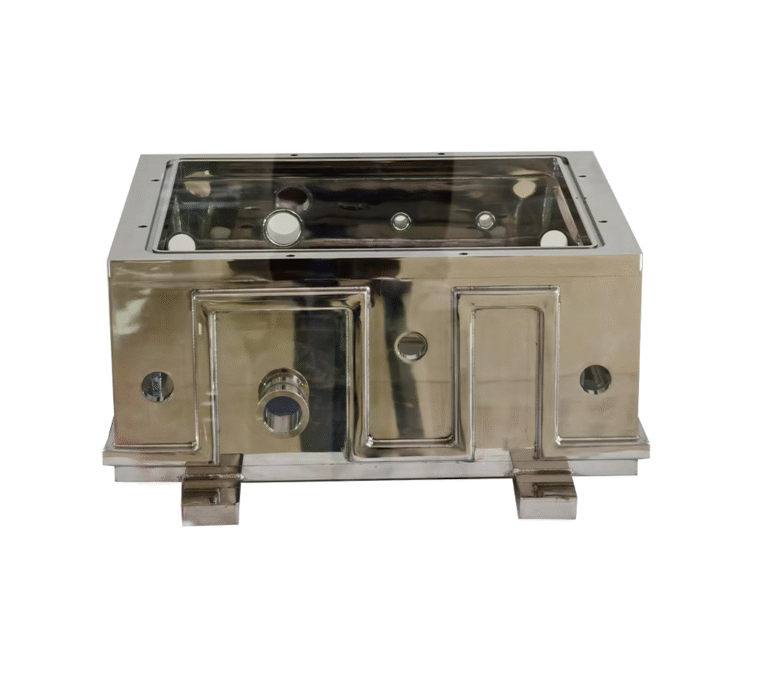

Large stainless steel chamber

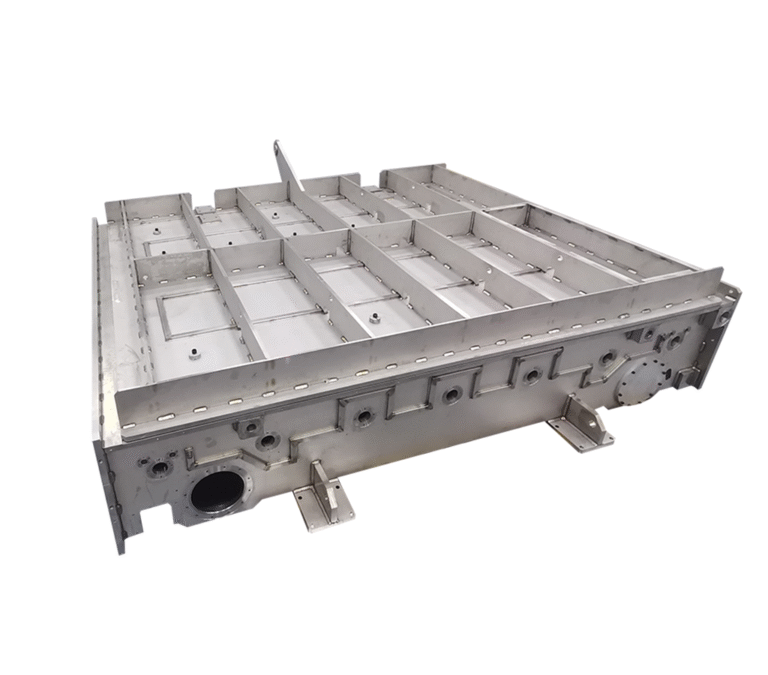

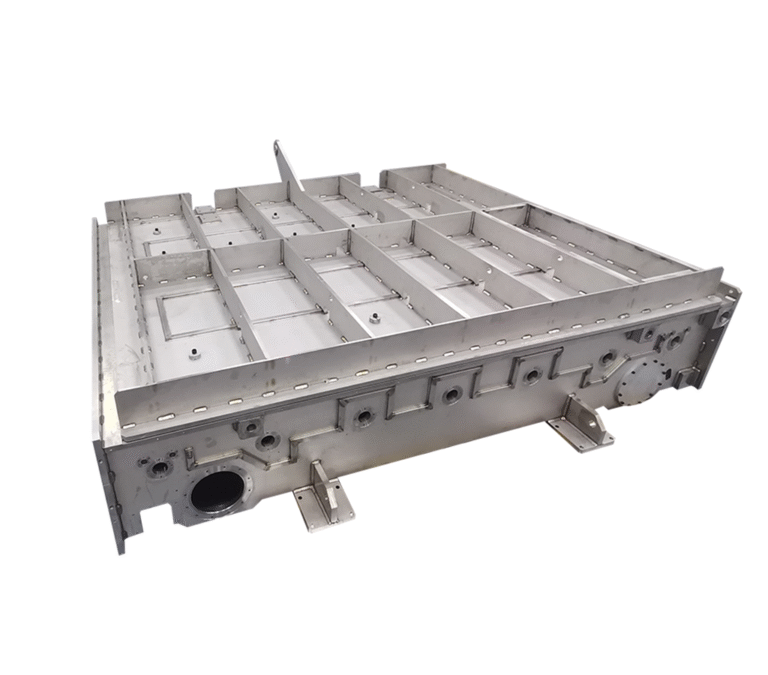

Large aluminum alloy chamber

Large aluminum alloy chamber

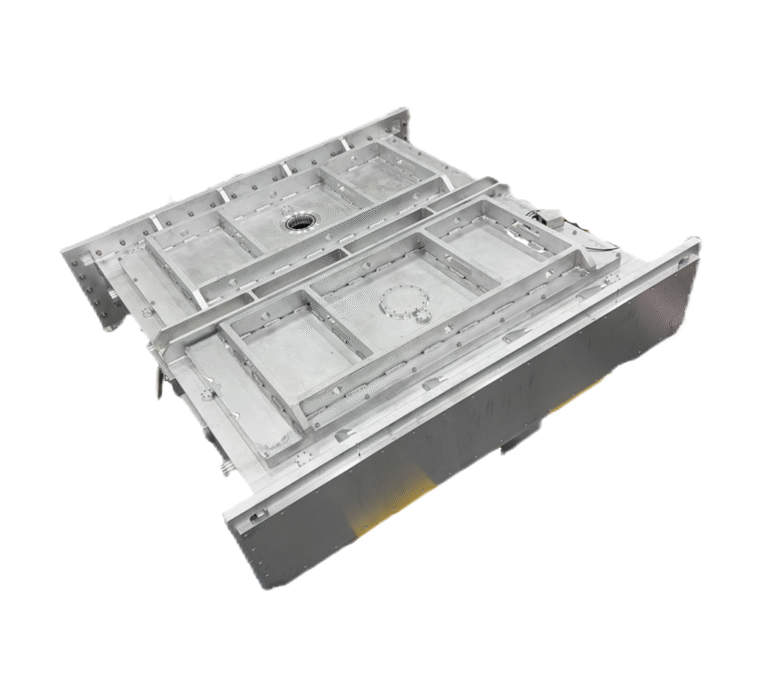

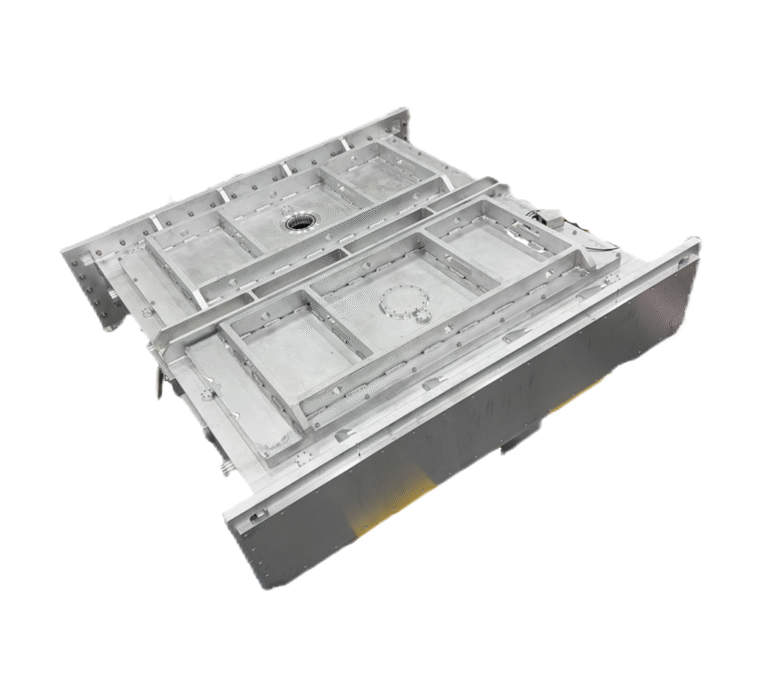

CVD four major components

backing plate

Diffuser

Shadow Frame

Susceptor

Meet any technical requirements of your products

Our key technological breakthroughs can make your products even better!

Vacuum requirements for different semiconductor processes

- Photolithography process

- General photolithography: 10^-3 ~ 10^-5 Pa

- EUV lithography: 10^-7 ~ 10^-9 Pa

- Thin film deposition process

- Physical vapor deposition (PVD): 10^-4 ~ 10^-6 Pa

- Chemical vapor deposition (CVD): 10^-4 ~ 10^-7 Pa

- Atomic layer deposition (ALD): 10^-6 ~ 10^-8 Pa

- Etching process

- Reactive ion etching (RIE): 10^-4 ~ 10^-6 Pa

- Deep reactive ion etching (DRIE): 10^-5 ~ 10^-7 Pa

- Ion implantation process

- Basic vacuum degree: 10^-5 ~ 10^-7 Pa

Why do we pursue ultra-high vacuum?

Impurity control

10^-7 Pa vacuum can significantly reduce the contamination of residual gas molecules (such as water, oxygen, hydrocarbons) to the process

Surface cleanliness

Under ultra-high vacuum, the time it takes for a surface contamination monolayer to form can be extended from a few seconds in ordinary high vacuum to several hours.

Yield improvement

Providing the necessary clean environment for 7nm and below process nodes

Uniformity assurance

ensuring the accuracy and uniformity of processes such as thin film deposition and ion implantation

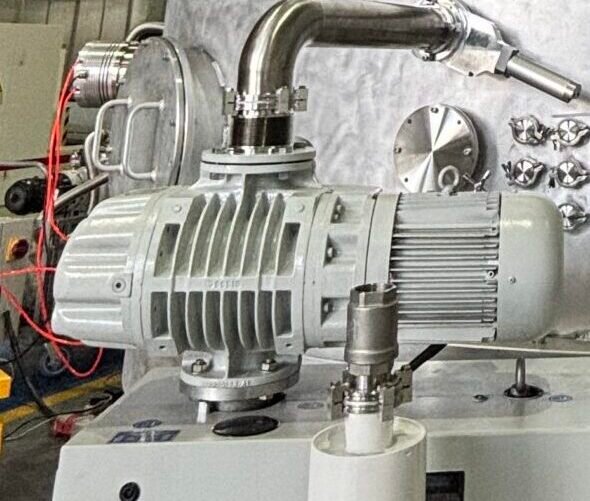

Challenges of Vacuum Chamber Welding

· Leak rate requirements

Usually the leakage rate is required to be lower than 1×10^-10 Pa·m³/s.

· Material outgassing

Special treatment is required to reduce the release of gas from the material.

· Weld quality

There must be no micropores or impurities to ensure long-term vacuum integrity.

The key significance of leak rate indicator in vacuum system

Leak rate is the most critical indicator to measure the sealing integrity of the vacuum system, which directly determines whether the system can reach and maintain the designed vacuum degree. For semiconductor process equipment, even a small leak may cause:

- The basic vacuum degree cannot meet the standard, affecting the purity control of subsequent process gases.

- Pollutants such as moisture and oxygen in the atmosphere continue to penetrate, interfering with the uniformity of film deposition.

- The formation of the surface adsorption layer is accelerated, reducing the interface quality and structural characteristics.

- The residual gas composition in the process chamber changes, affecting the ionization efficiency and energy distribution.

Ultra-high vacuum sealing technology

Through years of focused research and development, Leku has transformed the extremely low leakage rate control capability of <1.0×10^-13 Pa·m³/s into a core competitive advantage, and can provide you with truly “ultra-high vacuum grade” products that meet the stringent requirements of the most advanced semiconductor processes.

Integrate Class 10 clean technology into every manufacturing process to provide pure protection for your advanced processes

Class 10 clean environment control

- Particle concentration is less than 10/cubic foot (particles 0.5μm and larger)

- Real-time monitoring and automatic alarm system

- Precise temperature and humidity control (20±0.5℃, 45±2%RH)

Pollution-free manufacturing throughout the entire process

- Clean room partition management and airflow design

- Personnel training and strict operating procedures

- Dedicated purified gas delivery system

Trusted by leading semiconductor equipment manufacturers

What Our Clients Say

Ready to Enhance Your Semiconductor Equipment Performance?

Frequently Asked Questions

What is the highest vacuum level that LAIKU Semiconductor can achieve?

How does Class 10 cleanliness process differ from standard clean processes?

Class 10 (ISO 4) cleanliness process means fewer than 10 particles of 0.5μm or larger per cubic foot of air, which is 10-100 times more stringent than standard clean processes (typically Class 100 or 1000). LAIKU’s Class 10 process implementation includes full cleanroom production, specialized material purification treatments, proprietary surface processing techniques, and strict contamination control measures. These ensure our products meet the cleanliness requirements of contemporary advanced semiconductor processes, effectively preventing yield issues caused by micro-contamination.

How do you verify the vacuum performance and cleanliness of your products?

We employ a multi-layered verification system:

- Vacuum performance verification: Comprehensive testing using helium mass spectrometer leak detectors, capable of detecting leaks as small as 10^-12 Pa·m³/s

- Cleanliness verification: Methods including Residual Gas Analysis (RGA), surface microcontamination analysis, and particle counting

- Practical application testing: Long-term stability testing in actual working environments in cooperation with customers

Which semiconductor process stages are LAIKU's products suitable for?

Our high-vacuum chambers and components are widely used in critical semiconductor manufacturing process stages, including but not limited to:

- Lithography equipment vacuum systems

- Etching and thin film deposition equipment (PVD, CVD, ALD)

- Ion implantation equipment

- Surface treatment and cleaning processes

- Wafer inspection and metrology equipment

- HJT, perovskite, and other new photovoltaic manufacturing equipment We can provide customized solutions based on the specific requirements of different process stages.

What precision tolerances can LAIKU achieve for semiconductor vacuum chambers and components?

LAIKU achieves industry-leading precision tolerances for semiconductor components:

- Flatness control: ±0.025mm over 1000mm reference surfaces

- Perpendicularity: within 0.02mm/m for critical mounting surfaces

- Dimensional accuracy: ±0.05mm for features up to 500mm, scaling to ±0.1mm for larger dimensions

- Angular tolerances: ±0.05° for critical interfaces

- Surface roughness: Ra 0.2μm or better for vacuum-facing surfaces

- Parallelism: ±0.02mm between critical reference planes

- Concentricity: within 0.05mm for complex assemblies

- Bolt hole pattern accuracy: ±0.03mm for mating interfaces

Our precision capabilities are supported by advanced metrology systems including laser trackers, CMMs with volumetric accuracy of 1.5μm + L/350, and optical scanners with sub-micron resolution. We provide comprehensive dimensional reports with each delivery, including 3D mapping of critical surfaces where required.

Our Latest News

How to Overcome Quality Control Challenges in the Manufacturing of Ultra-High Vacuum Chambers

In Ultra-High Vacuum (UHV) manufacturing, quality control is not a compliance exercise; it is a strategic differentiator. At pressures below

How to Address Welding and Connection Technology Challenges in Ultra-High Vacuum Environments?

Ultra-high vacuum environments create significant challenges for welding and connections. Leaks, contamination, and material failures can compromise system performance and

How to Address Welding and Connection Technology Challenges in Ultra-High Vacuum Environments?

The demanding world of ultra-high vacuum systems presents persistent welding and connection challenges that compromise system integrity. Manufacturers face leakage,

Vacuum System Leak Detection Technology and Quality Assurance System

Vacuum leaks can devastate production lines, waste materials, and create costly delays. Finding these invisible problems quickly can mean the

Laiku announces the completion of a Class 100 cleanroom: Raising vacuum technology standards

We’re excited to announce that Laiku has completed installation of a new Class 100 (ISO 5) clean room at our

How Big Is the Vacuum Chamber Market?

In the ever-expanding world of technology, vacuum chambers hold a pivotal role. Are you curious about the size of this

High-Precision Vacuum

Solutions for

Semiconductor

Manufacturing

Custom-engineered high-vacuum chambers and components that meet the most demanding semiconductor process requirements.

Addressing Critical Challenges in Semiconductor Manufacturing

The semiconductor industry is currently facing many problems that need to be solved.

Modern semiconductor processes have increasingly higher requirements for chamber vacuum (<1×10^-7 Pa), and traditional manufacturing processes are difficult to meet the needs of advanced processes.

- Laiku has achieved a breakthrough in ultra-high vacuum (< 10^-7Pa ) technology, with a leakage rate (<1.0×10^-13 Pa·m³/s).

Precision control and deformation issues in large-size cavity processing. Poor deformation control will seriously affect the performance and yield of semiconductor equipment.

- Laiku has mastered high-precision deformation control technology, and the deformation tolerance is controlled within (±0.05mm/m).

Semiconductor processes have strict requirements on component cleanliness, and even a trace of contamination can lead to a decrease in chip yield

- Equipped with constant temperature and humidity welding rooms, Class 10,000, Class 1000 and Class 100 clean rooms, providing a full-process clean solution from processing to clean assembly.

The complex cavity structures in modern semiconductor devices require high-precision machining, especially for aluminum alloy parts that are difficult to weld.

- Provides a variety of advanced welding processes such as TIG welding and friction stir welding (FSW), especially suitable for complex geometries and high-quality joints in semiconductor device manufacturing.

The instability of the global supply chain has led to extended delivery times and unstable quality of core components of semiconductor equipment

- Providing complete supply chain services from raw materials, machining, welding to surface treatment and clean assembly can help you save time and improve efficiency

Semiconductor technology is rapidly iterating, and equipment manufacturers need partners who can quickly respond to customized needs

- Laiku focuses on providing customized solutions and has a team of high-end technical talents who can provide customers with customized services from chambers to complete systems.

Precision-Engineered Solutions for Semiconductor Equipment Manufacturers

The product series we provide are widely used in lithography, ion implantation, thin film deposition, dry etching and other links.

Spherical stainless steel vacuum chamber

Cylindrical stainless steel vacuum chamber

Square stainless steel vacuum chamber

Large stainless steel chamber

Large aluminum alloy chamber

Large aluminum alloy chamber

CVD four major components

backing plate

Diffuser

Shadow Frame

Susceptor

Meet any technical requirements of your products

Our key technological breakthroughs can make your products even better!

Vacuum requirements for different semiconductor processes

- Photolithography process

- General photolithography: 10^-3 ~ 10^-5 Pa

- EUV lithography: 10^-7 ~ 10^-9 Pa

- Thin film deposition process

- Physical vapor deposition (PVD): 10^-4 ~ 10^-6 Pa

- Chemical vapor deposition (CVD): 10^-4 ~ 10^-7 Pa

- Atomic layer deposition (ALD): 10^-6 ~ 10^-8 Pa

- Etching process

- Reactive ion etching (RIE): 10^-4 ~ 10^-6 Pa

- Deep reactive ion etching (DRIE): 10^-5 ~ 10^-7 Pa

- Ion implantation process

- Basic vacuum degree: 10^-5 ~ 10^-7 Pa

Why do we pursue ultra-high vacuum?

Impurity control

10^-7 Pa vacuum can significantly reduce the contamination of residual gas molecules (such as water, oxygen, hydrocarbons) to the process

Surface cleanliness

Under ultra-high vacuum, the time it takes for a surface contamination monolayer to form can be extended from a few seconds in ordinary high vacuum to several hours.

Yield improvement

Providing the necessary clean environment for 7nm and below process nodes

Uniformity assurance

ensuring the accuracy and uniformity of processes such as thin film deposition and ion implantation

Challenges of Vacuum Chamber Welding

· Leak rate requirements

Usually the leakage rate is required to be lower than 1×10^-10 Pa·m³/s.

· Material outgassing

Special treatment is required to reduce the release of gas from the material.

· Weld quality

There must be no micropores or impurities to ensure long-term vacuum integrity.

The key significance of leak rate indicator in vacuum system

Leak rate is the most critical indicator to measure the sealing integrity of the vacuum system, which directly determines whether the system can reach and maintain the designed vacuum degree. For semiconductor process equipment, even a small leak may cause:

- The basic vacuum degree cannot meet the standard, affecting the purity control of subsequent process gases.

- Pollutants such as moisture and oxygen in the atmosphere continue to penetrate, interfering with the uniformity of film deposition.

- The formation of the surface adsorption layer is accelerated, reducing the interface quality and structural characteristics.

- The residual gas composition in the process chamber changes, affecting the ionization efficiency and energy distribution.

Ultra-high vacuum sealing technology

Through years of focused research and development, Leku has transformed the extremely low leakage rate control capability of <1.0×10^-13 Pa·m³/s into a core competitive advantage, and can provide you with truly “ultra-high vacuum grade” products that meet the stringent requirements of the most advanced semiconductor processes.

Integrate Class 10 clean technology into every manufacturing process to provide pure protection for your advanced processes

Class 10 clean environment control

- Particle concentration is less than 10/cubic foot (particles 0.5μm and larger)

- Real-time monitoring and automatic alarm system

- Precise temperature and humidity control (20±0.5℃, 45±2%RH)

Pollution-free manufacturing throughout the entire process

- Clean room partition management and airflow design

- Personnel training and strict operating procedures

- Dedicated purified gas delivery system

Trusted by leading semiconductor equipment manufacturers

What Our Clients Say

Ready to Enhance Your Semiconductor Equipment Performance?

Frequently Asked Questions

What is the highest vacuum level that LAIKU Semiconductor can achieve?

How does Class 10 cleanliness process differ from standard clean processes?

Class 10 (ISO 4) cleanliness process means fewer than 10 particles of 0.5μm or larger per cubic foot of air, which is 10-100 times more stringent than standard clean processes (typically Class 100 or 1000). LAIKU’s Class 10 process implementation includes full cleanroom production, specialized material purification treatments, proprietary surface processing techniques, and strict contamination control measures. These ensure our products meet the cleanliness requirements of contemporary advanced semiconductor processes, effectively preventing yield issues caused by micro-contamination.

How do you verify the vacuum performance and cleanliness of your products?

We employ a multi-layered verification system:

- Vacuum performance verification: Comprehensive testing using helium mass spectrometer leak detectors, capable of detecting leaks as small as 10^-12 Pa·m³/s

- Cleanliness verification: Methods including Residual Gas Analysis (RGA), surface microcontamination analysis, and particle counting

- Practical application testing: Long-term stability testing in actual working environments in cooperation with customers

Which semiconductor process stages are LAIKU's products suitable for?

Our high-vacuum chambers and components are widely used in critical semiconductor manufacturing process stages, including but not limited to:

- Lithography equipment vacuum systems

- Etching and thin film deposition equipment (PVD, CVD, ALD)

- Ion implantation equipment

- Surface treatment and cleaning processes

- Wafer inspection and metrology equipment

- HJT, perovskite, and other new photovoltaic manufacturing equipment We can provide customized solutions based on the specific requirements of different process stages.

What precision tolerances can LAIKU achieve for semiconductor vacuum chambers and components?

LAIKU achieves industry-leading precision tolerances for semiconductor components:

- Flatness control: ±0.025mm over 1000mm reference surfaces

- Perpendicularity: within 0.02mm/m for critical mounting surfaces

- Dimensional accuracy: ±0.05mm for features up to 500mm, scaling to ±0.1mm for larger dimensions

- Angular tolerances: ±0.05° for critical interfaces

- Surface roughness: Ra 0.2μm or better for vacuum-facing surfaces

- Parallelism: ±0.02mm between critical reference planes

- Concentricity: within 0.05mm for complex assemblies

- Bolt hole pattern accuracy: ±0.03mm for mating interfaces

Our precision capabilities are supported by advanced metrology systems including laser trackers, CMMs with volumetric accuracy of 1.5μm + L/350, and optical scanners with sub-micron resolution. We provide comprehensive dimensional reports with each delivery, including 3D mapping of critical surfaces where required.

Our Latest News

How to Overcome Quality Control Challenges in the Manufacturing of Ultra-High Vacuum Chambers

In Ultra-High Vacuum (UHV) manufacturing, quality control is not a compliance exercise; it is a strategic differentiator. At pressures below

How to Address Welding and Connection Technology Challenges in Ultra-High Vacuum Environments?

Ultra-high vacuum environments create significant challenges for welding and connections. Leaks, contamination, and material failures can compromise system performance and

How to Address Welding and Connection Technology Challenges in Ultra-High Vacuum Environments?

The demanding world of ultra-high vacuum systems presents persistent welding and connection challenges that compromise system integrity. Manufacturers face leakage,

Vacuum System Leak Detection Technology and Quality Assurance System

Vacuum leaks can devastate production lines, waste materials, and create costly delays. Finding these invisible problems quickly can mean the

Laiku announces the completion of a Class 100 cleanroom: Raising vacuum technology standards

We’re excited to announce that Laiku has completed installation of a new Class 100 (ISO 5) clean room at our

How Big Is the Vacuum Chamber Market?

In the ever-expanding world of technology, vacuum chambers hold a pivotal role. Are you curious about the size of this