In the intricate world of vacuum technology, the adage "a chain is only as strong as its weakest link" holds especially true. The effectiveness and reliability of vacuum systems, whether used in semiconductor manufacturing or advanced research labs, hinge on the quality of their components. Without supreme quality components, achieving and maintaining the desired vacuum levels can become an overwhelming challenge. This article delves into the critical components that constitute high-performing vacuum systems and the significance of their quality in ensuring precision and efficiency.

Understanding the Importance of Supreme Quality

Components used in vacuum technology are subjected to stringent conditions, including extreme pressures and high temperatures. The materials and engineering precision required to meet these challenges are paramount. For instance, vacuum chambers, seals, and pumps must exhibit exceptional durability and minimal outgassing properties to maintain high-performance standards. Investing in top-tier components reduces the risk of system failure, ensures longer operational life, and enhances overall performance, ultimately leading to cost efficiencies in long-term operations.

Key Components in Vacuum Technology

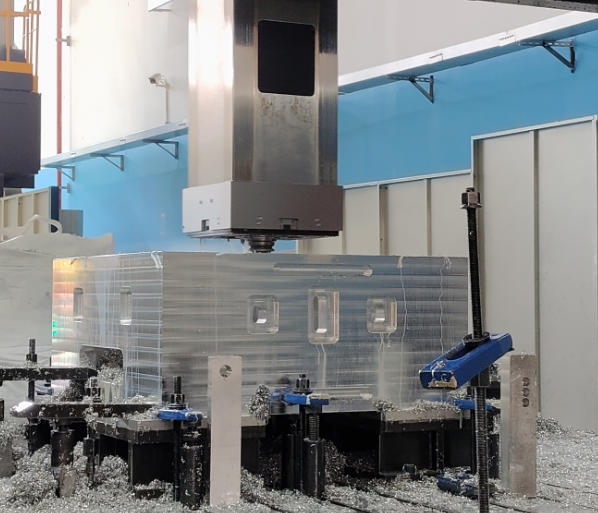

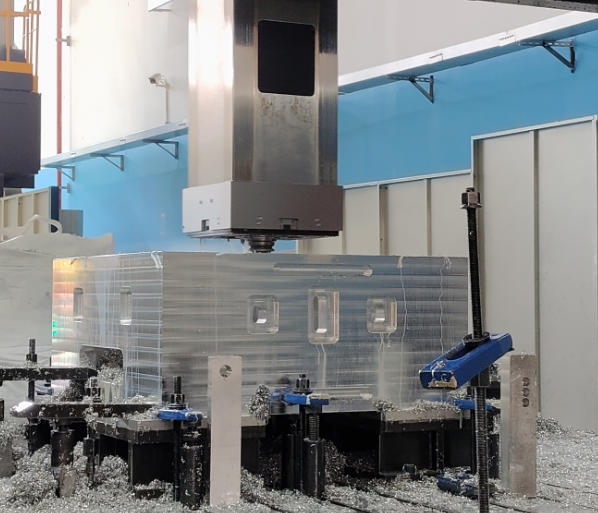

Vacuum Chambers

At the heart of any vacuum system lies the vacuum chamber, designed to withstand significant pressure differentials. Supreme quality chambers are typically constructed from materials such as stainless steel or aluminum alloys known for their low outgassing rates and mechanical strength. These materials prevent contamination and are often finished with electropolishing or anodizing to improve their corrosion resistance and longevity.

Vacuum Pumps

Vacuum pumps are the workhorses that create the necessary pressure environment. Whether it’s rotary vane pumps, turbomolecular pumps, or cryogenic pumps, the choice depends on the specific application and vacuum level required. High-quality pumps offer not only superior performance but also reduced maintenance needs and operational quietness, enhancing the user experience and operational efficiency.

Seals and Gaskets

Seals and gaskets, though often overlooked, are crucial for maintaining vacuum integrity. Made from materials like Viton or PTFE, they must resist chemical degradation and tolerate vast temperature ranges. A minor defect or material fatigue can lead to vacuum leaks, causing system failures. Quality seals ensure that connections remain airtight under all operating conditions.

Custom Solutions for Specialized Applications

Certain applications demand customized vacuum solutions. Companies like Laiku provide tailored vacuum components that cater to specific industry needs, such as custom chamber sizes or specialized coatings to reduce particle contamination. This level of customization ensures that the systems not only meet but exceed industry standards, providing a competitive edge in technology-driven markets.

Conclusion

In conclusion, supreme quality components form the backbone of robust vacuum systems. By prioritizing quality in materials and manufacturing processes, industries can achieve greater reliability, precision, and efficiency in their vacuum applications. As the demands in technology and research continue to evolve, so too must the standards for quality in vacuum components. By adhering to these high standards, companies ensure their systems are future-proof and capable of meeting the challenges of tomorrow’s technological advancements.

Investing in superior quality components is not just a choice but a necessity to ensure excellence in vacuum technology applications. Whether for semiconductors or scientific experimentation, the foundation of supreme quality is what elevates performance to its highest potential.