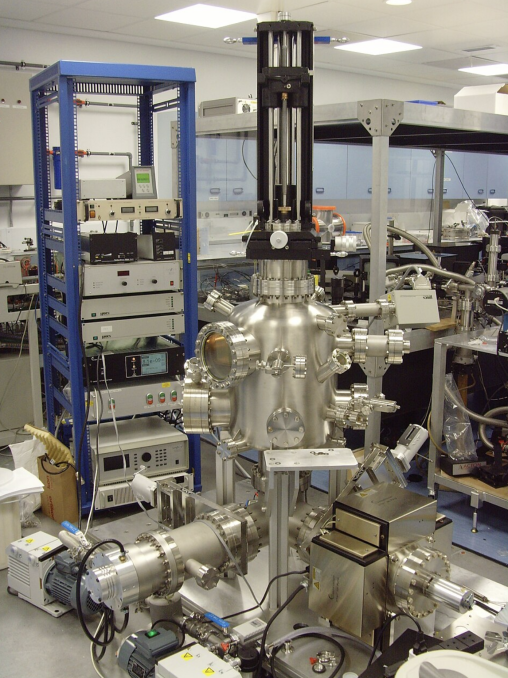

In Ultra-High Vacuum (UHV) manufacturing, quality control is not a compliance exercise; it is a strategic differentiator. At pressures below 10⁻⁹ mbar, there is no margin for error. Small oversights in material choice, surface preparation, or assembly practice can translate into unstable vacuum performance or unreliable process results.

Ultra-High Vacuum chambers form the foundation of modern semiconductor manufacturing. They enable atomic-level deposition, inspection, and surface modification, where process outcomes depend directly on vacuum integrity. Unlike conventional pressure vessels or mechanical assemblies, Ultra-High Vacuum chambers are governed as much by surface chemistry and time-dependent material behavior as by mechanical design.

For equipment manufacturers, wafer fabrication, and research laboratories, overcoming Ultra-High Vacuum quality challenges requires treating quality control as a system-wide discipline that spans across design, fabrication, cleaning, testing, integration, and long-term operation.

Source: https://commons.wikimedia.org/wiki/File:G_fs_UHV_chamber_rm_121_(8652722688).jpg#filelinks

Why Quality Control Is Uniquely Difficult in Ultra-High Vacuum Manufacturing

Ultra-High Vacuum systems are rarely judged by visible defects. Their performance is determined by what cannot be seen: residual gas species, surface outgassing, permeation through materials, virtual leaks, and atomic-scale contamination. In many cases, chambers pass factory acceptance tests only to exhibit problems after installation, when they fail to reach target base pressure or show unstable behavior during processing.

Three factors make quality control in Ultra-High Vacuum manufacturing fundamentally different from conventional manufacturing:

- Extreme sensitivity to contamination at the molecular and atomic level

- Time-dependent material and surface behavior under vacuum and thermal cycling

- The need for stable vacuum performance over years of continuous operation

Challenges and Control Measures

source: https://gemini.google.com/share/6cac8197aa2f

1. Material Selection and Surface Integrity

The challenge:

Materials commonly used in Ultra-High Vacuum chambers, such as stainless steel, aluminum alloys, and specialized coatings, can become long-term sources of contamination if not properly selected and processed. Microscopic surface roughness, trapped hydrocarbons, poorly vented geometries, or marginal welds can lead to persistent outgassing and virtual leaks.

At Ultra-High Vacuum pressures, even minimal outgassing can compromise a chamber’s ability to meet its performance specifications.

Control measures:

- Use Ultra-High Vacuum qualified materials with well-characterized outgassing behavior (e.g., 304L/316L stainless steel, aluminum alloys, titanium)

- Design out virtual leaks by avoiding blind-tapped holes, trapped volumes, and unvented fasteners

- Apply electropolishing to reduce surface roughness and minimize gas adsorption sites

- Qualify welding procedures to ensure full penetration, low porosity, and repeatability

Decisions made at the design and fabrication stage often determine whether a chamber will remain stable years into operation.

2. Contamination During Manufacturing and Assembly

The challenge:

Contamination introduced during fabrication or assembly is a leading cause of degraded Ultra-High Vacuum performance. Lubricants, machining residues, airborne particles, moisture, and improper handling can adhere to internal surfaces and dominate outgassing behavior long after installation.

Once contamination is embedded, removal becomes difficult and, in some cases, impractical.

Control measures:

- Assemble Ultra-High Vacuum components in controlled cleanroom environments

- Enforce multi-stage cleaning protocols, including ultrasonic cleaning, solvent degreasing, deionized water rinsing, and vacuum baking

- Prohibit bare-hand contact with internal surfaces; use dedicated tools, gloves, and clean packaging

- Minimize exposure to ambient air between final cleaning and sealing to limit water adsorption

3. Leak Detection Beyond Conventional Standards

The challenge:

Leaks in Ultra-High Vacuum systems are often microscopic. Micro-leaks, permeation through seals, or marginal weld defects may pass standard pressure tests but fail under Ultra-High Vacuum conditions. Leak rates acceptable in high-vacuum systems can be unacceptable at Ultra-High Vacuum levels.

In addition, even perfectly sealed chambers retain adsorbed water on internal surfaces, which must be removed through proper baking procedures.

Control measures:

- Perform helium mass spectrometry leak testing at Ultra-High Vacuum relevant sensitivity levels

- Test critical components welds, flanges, feedthroughs individually, not just at the system level

- Use metal sealing technologies instead of elastomers wherever possible

- Verify leak integrity after thermal cycling, not only at room temperature

4. Long-Term Vacuum Stability and Aging Effects

The challenge:

A chamber that meets specifications during acceptance testing may degrade over time due to material aging, coating wear, repeated bake cycles, or exposure to aggressive process chemistries. In production environments, this degradation directly affects uptime and yield.

Control measures:

- Conduct accelerated aging and thermal cycling tests during qualification

- Monitor trends in base pressure and recovery time, not just absolute values

- Design chambers for maintainability, allowing components to be serviced or replaced without full disassembly

- Use predictive maintenance indicators based on vacuum behavior

5. Vacuum Consistency Across Clustered Chambers

The challenge:

In modern semiconductor tools, Ultra-High Vacuum chambers rarely operate in isolation. Cluster tools connect multiple chambers through shared transfer environments, meaning a single poorly controlled module can contaminate the entire system.

Control measures:

- Validate material compatibility with process gases, plasmas, and chemistries

- Standardize vacuum interfaces and wafer transfer protocols

- Assess cross-contamination risks during system integration

- Test vacuum recovery performance following wafer transfer and load-lock cycles

Adoption of Data-Driven Quality Control

Traditional pass/fail inspection is no longer sufficient for Ultra-High Vacuum manufacturing. Leading equipment suppliers and facilities are adopting data-driven quality control methods, including continuous pressure monitoring, residual gas analysis (RGA), statistical process control (SPC), and digital traceability of materials and process steps.

This approach enables early detection of performance degradation, reduces unplanned downtime, and supports long-term vacuum performance assurance.

Conclusion

Overcoming quality control challenges in Ultra-High Vacuum chamber manufacturing requires more than tighter tolerances or additional inspection steps. It demands a holistic approach that integrates material science, contamination control, advanced testing, and lifecycle monitoring.

For semiconductor equipment manufacturers, wafer fabs, and research institutions, treating Ultra-High Vacuum quality control as a system-level discipline and not as a final checkpoint will lead to higher yields, more stable processes, and more reliable scientific and manufacturing outcomes.