In the semiconductor equipment manufacturing sector, selecting the appropriate material for vacuum chambers is a critical decision that directly impacts equipment performance and longevity. The material selection directly influences vacuum levels, corrosion resistance, thermal stability, and the overall lifespan of the chamber. This article explores the key considerations when selecting vacuum chamber materials for semiconductor equipment, helping manufacturers make informed choices.

Understanding Vacuum Environment Requirements

Before selecting materials, it's essential to clearly understand the vacuum requirements of your application. Semiconductor manufacturing environments typically require high vacuum (10^-3 to 10^-7 Torr) or ultra-high vacuum (below 10^-7 Torr, reaching up to 10^-12 Torr). Different manufacturing processes demand different vacuum levels; for instance, photolithography, etching, and thin film deposition in semiconductor manufacturing require extremely high vacuum conditions to effectively prevent particle contamination and improve production yields. The selected material must maintain stability under these stringent conditions without excessive outgassing.

Comparison of Mainstream Materials

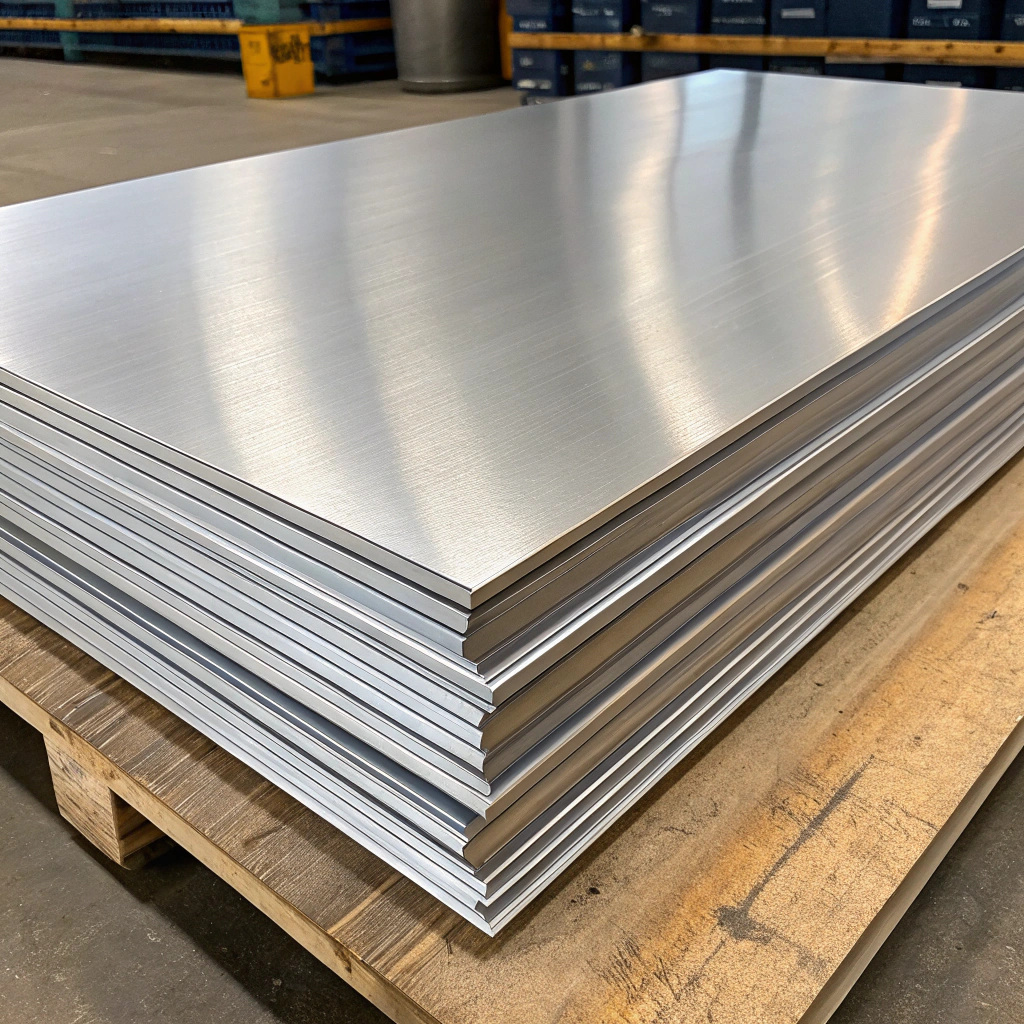

The most commonly used materials for vacuum chambers include aluminum alloys, stainless steel, and titanium, each offering unique advantages for specific applications.

Aluminum alloys are preferred for their lightweight properties, excellent thermal conductivity, and cost-effectiveness, making them ideal for projects requiring large-sized chambers with budget constraints. The design and materials of the chamber directly affect the sealing and stability of the vacuum system. However, aluminum shows limitations in chemically aggressive environments or ultra-high vacuum applications.

Stainless steel provides outstanding durability, corrosion resistance, and low outgassing rates, making it an ideal choice for a wide range of vacuum applications. It can withstand higher operating temperatures, offers good structural stability, and is particularly suitable for high and ultra-high vacuum applications. Materials used in HV and UHV systems must have low outgassing rates to minimize contamination and pressure increases. Common materials include stainless steel, aluminum, and ceramics, with surfaces often electropolished to reduce gas absorption and desorption.

Titanium stands out for its superior strength-to-weight ratio and exceptional corrosion resistance, making it ideal for specialized applications where these properties are critical, albeit at a higher cost. In cutting-edge applications requiring special performance characteristics, titanium's value is undeniable.

Practical Considerations in Material Selection

When making a practical selection, multiple factors must be considered comprehensively. First, thoroughly analyze your application's specific requirements for vacuum level, operating temperature, chemical environment, and mechanical strength. Second, weigh the initial material cost against long-term performance, including lifespan, maintenance requirements, and potential for upgrades. Finally, seek advice from professional suppliers who typically possess rich industry experience and technical knowledge.

Material quality control is essential to ensure vacuum chambers meet requirements and have longer service lives. Professional material testing and certification processes can verify that materials meet the necessary standards for vacuum applications.

Vacuum chambers are essential components in many industrial and research applications, including semiconductor manufacturing, materials science research, and space simulation tests. The choice of material for a vacuum chamber is crucial and depends on the specific requirements of the application, such as vacuum level, chemical resistance, mechanical properties, and cost.

Application Scope in Semiconductor Industry

In the semiconductor industry, vacuum chambers serve critical functions across various manufacturing processes. High Vacuum (HV) and Ultra-High Vacuum (UHV) environments are essential for semiconductor fabrication to prevent contamination that could lead to defects in microchips. The semiconductor manufacturing process demands extremely high vacuum conditions, particularly in photolithography, etching, and thin film deposition.

Additionally, vacuum chambers are used for applying thin films of materials onto substrates through techniques like sputtering or evaporation (PVD, CVD, FPD). This is critical in creating coatings for optics, electronics, and wear-resistant materials.

Material Recommendations Based on Application

The most popular material for vacuum chambers is stainless steel. Especially 304 stainless steel is extensively utilized in the construction of vacuum chambers due to its high strength and suitability for wide temperature variations.

For applications requiring lightweight properties combined with good thermal management, aluminum alloys such as 6061-T6, 7075-T6, 5083, 2024, MIC6, and 5052 are excellent choices.

In highly corrosive environments or when exceptional strength-to-weight ratio is needed, titanium becomes the material of choice despite its higher cost.

Conclusion

Selecting the appropriate vacuum chamber material is a critical step in ensuring the performance of semiconductor manufacturing equipment. By understanding the characteristics of different materials, clarifying your application requirements, and choosing reliable suppliers, you can find the optimal vacuum chamber material solution for your semiconductor equipment. Throughout this process, professional technical support and comprehensive services can help you achieve a perfect transition from design to manufacturing, ensuring your equipment meets the highest standards of performance and reliability.