Introduction

Chemical Vapor Deposition (CVD) stands as a cornerstone technology in the semiconductor manufacturing industry and materials science field. At the heart of this sophisticated process lies the vacuum chamber - a critical component that directly influences process efficacy and product quality. This article explores the pivotal role of vacuum chambers in CVD equipment, highlighting key technical requirements, structural considerations, and emerging trends that are shaping the industry's future.

Understanding CVD Process Requirements for Vacuum Chambers

The Chemical Vapor Deposition process involves depositing solid films through controlled chemical reactions of gaseous precursors in a vacuum environment. This process demands vacuum chambers that meet stringent technical specifications:

-

High Vacuum Environment Maintenance: CVD processes typically require high vacuum conditions (ranging from 10^-3 to 10^-7 Torr) to minimize contamination and ensure precise control over the deposition process.

-

Material Purity and Low Outgassing Rates: Chamber materials must exhibit low outgassing rates to maintain environmental purity. Common materials include stainless steel, aluminum alloys, and ceramics, with surfaces often electropolished to reduce gas absorption and release.

-

Advanced Sealing Technology: Effective sealing is paramount in preventing atmospheric leakage into the vacuum environment. For high-precision CVD applications, metal seals are often preferred over elastomeric alternatives due to their superior outgassing performance.

Structural Design of Vacuum Chambers for CVD Equipment

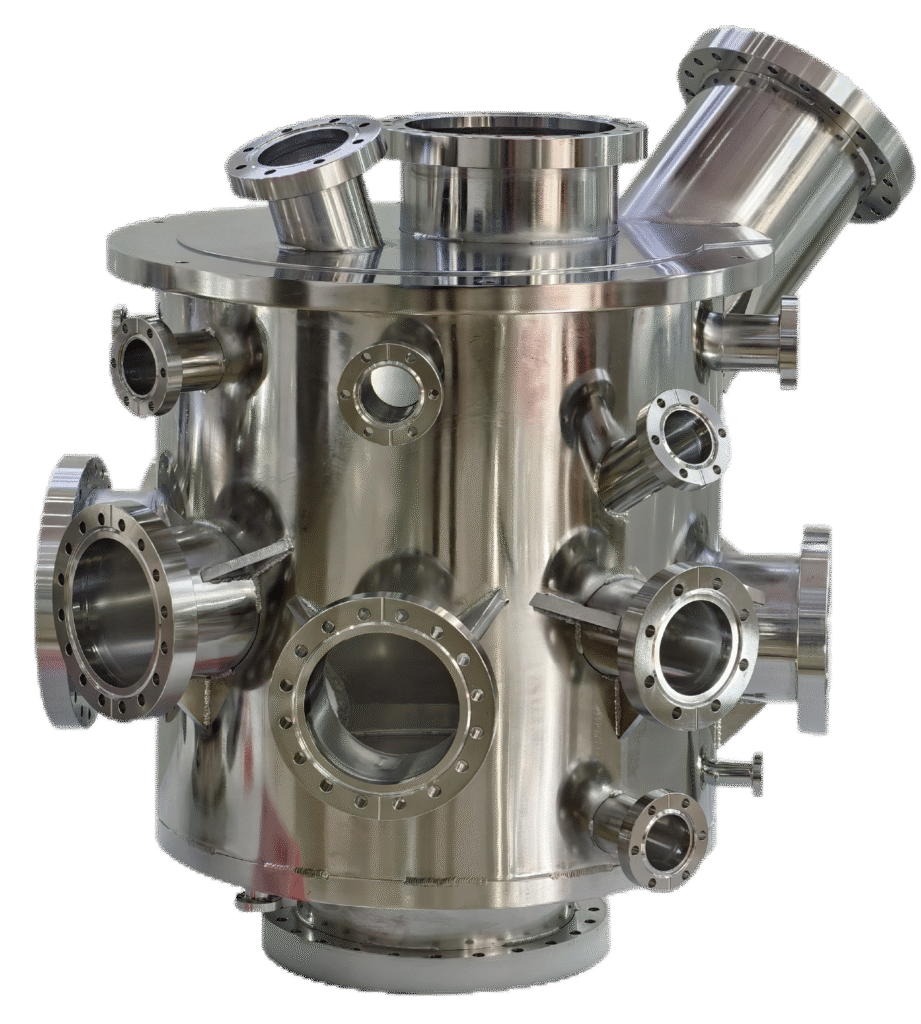

Cylindrical Vacuum Chambers

Cylindrical chambers represent the most common design in CVD equipment:

-

Structural Advantages: These chambers offer an optimal balance between volume and surface area, providing excellent structural stability under vacuum conditions.

-

Versatile Configuration: Cylindrical chambers can be positioned horizontally or vertically to accommodate various application requirements and substrate geometries.

-

Application Range: Due to their ability to accommodate lengthy substrates, cylindrical vacuum chambers find extensive use in semiconductor and coating industries for both Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) processes.

Critical Design Considerations

In semiconductor manufacturing, vacuum chamber design must address several key factors:

-

Uniform Gas Flow Distribution: CVD processes demand uniform distribution of reactant gases within the chamber, necessitating specialized internal structural designs.

-

Temperature Management: Many CVD processes operate at elevated temperatures, requiring chambers designed to withstand thermal stress while maintaining consistent temperature distribution.

-

Contamination Minimization: Proper welding techniques are essential to minimize contamination risks within the chamber - a critical consideration for high-purity environments required in semiconductor manufacturing.

Vacuum Chamber Applications Across Different CVD Scenarios

Semiconductor Manufacturing

In the semiconductor industry, CVD vacuum chambers serve specialized functions:

-

Ultra-Clean Environment: High and ultra-high vacuum environments are essential for semiconductor fabrication, preventing contaminants that could lead to microchip defects.

-

Precise Vacuum Measurement: Accurate pressure measurement ensures each production step operates within specified vacuum parameters, directly affecting process stability and product quality.

Optical and Nanotechnology Applications

CVD vacuum chambers also play vital roles in optical research and nanotechnology fields:

-

Optical Research: Optical studies require high-precision dust-free environments, such as high or ultra-high vacuum systems. The purity of the vacuum environment directly determines the precision of optical components during manufacturing and testing.

-

Nanotechnology: Fabrication and research of nanoscale materials and devices often require ultra-high vacuum conditions to ensure surface purity and enable precise manipulation at atomic and molecular levels.

Vacuum Chamber Maintenance and Modification

Long-term use of vacuum chambers may necessitate maintenance or modification:

-

Repair and Modification: Over time, vacuum chambers may require repairs due to wear or modifications to accommodate new processes or equipment. Welding provides a versatile method for repairing damage (such as cracks or leaks) and implementing modifications (like adding new ports or altering chamber dimensions) .

-

Contamination Prevention: Proper welding techniques minimize contamination risks inside the chamber - crucial for processes requiring high-purity environments, such as semiconductor manufacturing or materials science experiments .

Advanced Cleaning and Post-Processing

The performance of CVD vacuum chambers is significantly enhanced through specialized post-processing:

-

Professional Cleaning: State-of-the-art purification workshops ensure the removal of impurities and oil stains from newly completed vacuum chambers - a level of cleaning that exceeds visual inspection capabilities.

-

Cleanroom Processing: Class 10000 cleanrooms containing fewer than 352,000 particles larger than 0.5 microns per cubic foot of air provide the controlled environment necessary for inspection, assembly, and packaging of critical components under strict cleanliness standards.

-

Surface Finishing Options: Expert application of various finishes - including Glass Bead Blasted, Machine Polished, Sandblasted, and Electropolished - ensures optimal surface properties for specific applications. Standard offerings typically include flanges and precision-machined components with a 32-microinch surface finish, and ultra-refined 16-microinch finish on sealing surfaces.

Conclusion

Vacuum chambers represent the cornerstone of CVD equipment, with their design, material selection, and manufacturing processes directly impacting CVD process effectiveness and product quality. As semiconductor manufacturing processes continue to evolve and nanotechnology applications expand, technical requirements for vacuum chambers will become increasingly stringent.

The future of vacuum chamber technology is advancing toward higher vacuum levels, more precise deformation control, reduced contamination risk, and smarter monitoring systems. These advancements will provide even more robust infrastructure support for continued progress in semiconductor manufacturing and materials science fields, ensuring that innovation and precision craftsmanship remain at the forefront of this critical industry.