Vacuum chambers are vital for precision. But what makes a customization service truly professional?

A professional vacuum chamber customization service focuses on manufacturing capability, custom options, and stringent quality control. We offer an end-to-end supply chain, ensuring smooth project completion[^5].

Let's explore the key elements you should consider when choosing a vacuum chamber customization service.

What technical support is needed for customized vacuum chamber?

Got tricky technical issues? You need solid technical support for your customized vacuum chamber.

Custom vacuum chambers require broad technical support, covering design, material selection, and process guidance. Our expert engineers are ready to bring your vision to life.

Technical support is crucial in vacuum chamber customization. A good supplier provides complete support, from design to manufacturing. This includes:

- Design Optimization: They should optimize the chamber design for your application. Shape, size, and port placement matter.

- Material Selection: Different materials suit different applications. Stainless steel is great for clean environments, while aluminum excels in thermal conductivity.

- Process Guidance: Professional guidance is needed to ensure proper manufacturing, including welding and surface treatment.

A responsive and problem-solving technical team is essential. Our team is ready to support your project, leveraging decades of experience in semiconductor, photovoltaic, and scientific instrument customization.How to choose the right vacuum chamber material and design according to the requirements?

Tons of options in materials and designs. How do you pick the best for your vacuum chamber?

Choosing the right material and design means considering the application, vacuum needs, and budget. We offer materials like stainless steel and aluminum, tailoring designs to your requirements.

The right material and design secure top vacuum system performance. Think about these points:

- Application: Different fields have different needs. Semiconductor, Vacuum Coating and Deposition and FPD are the main application of our company.

- Vacuum Level: Higher vacuum needs dictate specific materials and sealing.

- Budget: Costs vary greatly. Balance performance and price.

Common materials include stainless steel and aluminum. Stainless steel is strong and corrosion-resistant. Aluminum offers good heat transfer and light weight. Our team can recommend the best options for you.What is the manufacturing process of vacuum chamber?

Curious about vacuum chamber creation? Each step is key.

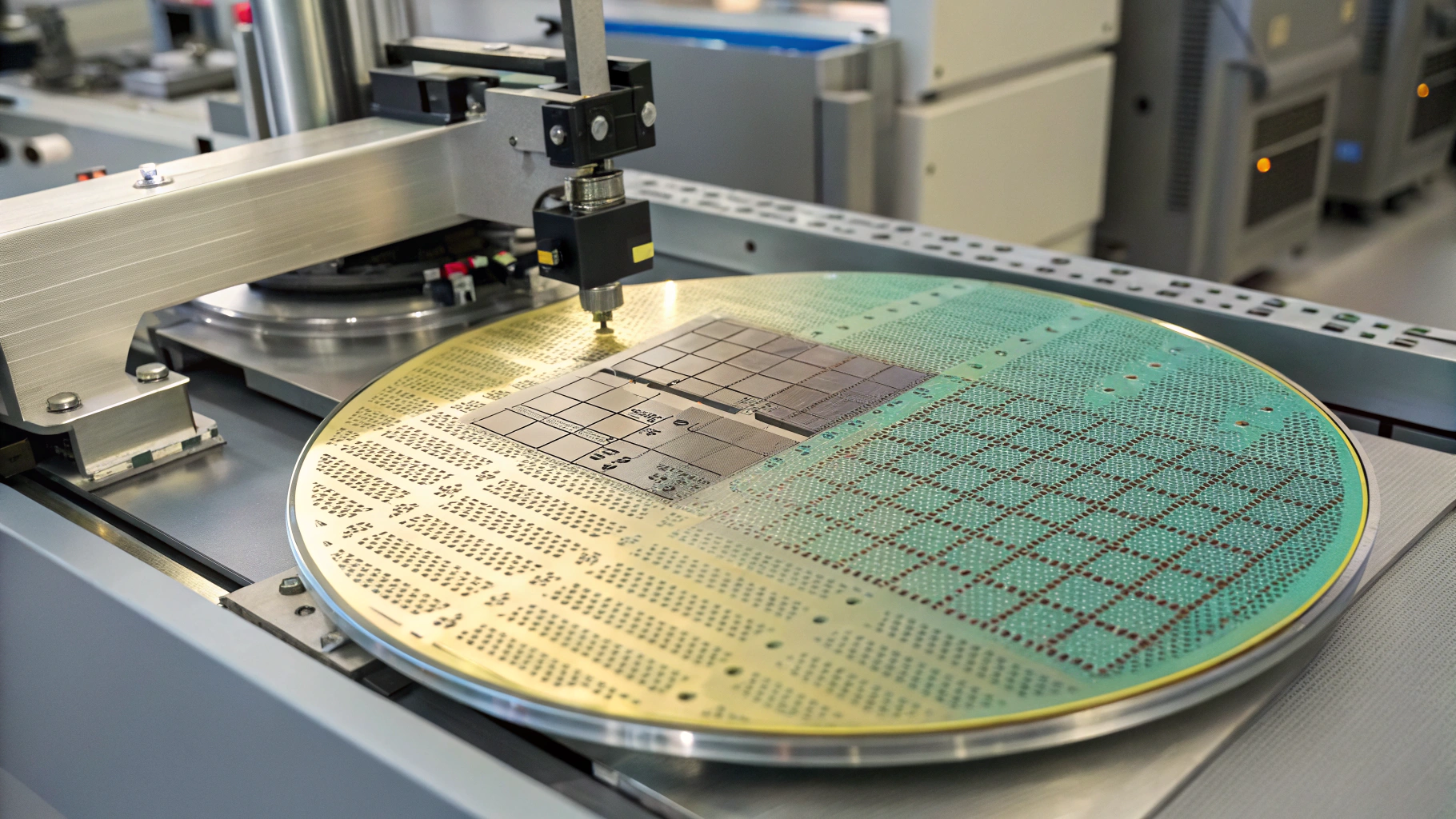

The process includes material selection, CNC machining, welding, surface treatment, and clean assembly. We use an end-to-end supply chain, controlling each step to ensure quality.

Manufacturing a vacuum chamber is intricate, demanding strict quality and expert craftsmanship. Key steps include:- Material Selection: Choosing materials like stainless steel or aluminum.

- CNC Machining: Precision machining to shape the material.

- Welding: Joining parts using TIG or laser welding. Weld quality impacts sealing and strength.

- Surface Treatment: Improving corrosion resistance and cleanliness with polishing, anodizing, etc.

- Clean Assembly: Assembling in a cleanroom to eliminate dust and oil.

- Helium Leak Testing: Ensuring leak rates meet specification.

We use advanced equipment and skilled teams to control each step. Our end-to-end approach guarantees efficient, high-quality results.How can suppliers ensure the quality of vacuum chambers?

Vacuum chamber quality varies. How do suppliers guarantee reliability?

Quality control measures, such as helium leak tests, material checks, and dimensional inspections, ensure vacuum chamber quality.

Quality is vital. Key measures include:

- Material Testing: Analyzing material composition and properties.

- Dimensional Inspection: Measuring dimensions with equipment.

- Weld Inspection: Using X-rays or ultrasound to check weld quality.

- Helium Leak Testing: Testing for leaks with helium leak detectors.

- Residual Gas Analysis (RGA): Analyzing gases inside the chamber for cleanliness.

We adhere to quality management systems, ensuring quality at every step. We also offer RGA for cleanliness assurance.What kind of customer support and after-sales service is provided?

Peace of mind after buying? Know your supplier's support and services.

We provide comprehensive support: maintenance, technical support. Our goal is to provide you with the best experience.

Good support is key. Common services include: - Maintenance: Regular maintenance and repairs.

- Technical Support: Troubleshooting and advice.

- Custom Solutions: Tailoring solutions to unique needs.

Our service team responds quickly. We provide remote and on-site support to keep your vacuum systems running.Conclusion

Choosing a vacuum chamber customization service requires careful consideration. With our full-chain supply model and vast experience, we deliver top products and support.

One Response

Simply desire to say your article is aas astounding.

The clearnjess for your post iss simply spectacular

and i ccould suppose you’re an expert in this subject.

Fine along with your permission allow me to snatch your RSS feed to stay updated with forthcoming post.

Thank you a million and please continue the rewarding work. http://Boyarka-inform.com/